Implementation of workplace safety management policy

Shape an occupational health and safety culture

Through commitment and action, Advantech strives to create an occupational safety and health culture. Adopting a core strategy of promoting occupational health and safety management, the aim is to minimize workplace accidents by enhancing safety awareness, behaviors and habits, and fostering a strong safety culture. The headquarters not only complies with regulations in Taiwan but also pays attention to important global occupational health and safety-related topics to create a healthy and injury-free workplace, in turn decreasing impacts and risks on stakeholders. Therefore, the priority is to establish an occupational health and safety management system that controls risks and enhances employees’ safety awareness, with the goal of creating a healthy, safe, accident-free, and high-quality workplace.

Occupational health and safety management system (ISO 45001:2018)

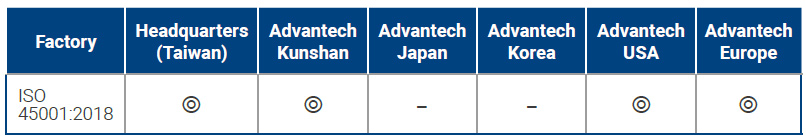

Advantech is committed to providing a safe and healthy workplace. We have established and implemented an ISO 45001–compliant Occupational Health and Safety Management System (OHSMS) and, in 2024, required every plant to adopt systematic management in accordance with ISO 45001. Our Occupational Health and Safety Management Policy was approved by the Board of Directors, implemented company-wide, and publicly disclosed on our website.

The OHSMS covers all workers, including Advantech employees and non-employee workers. From the corporate level down—and across regions—dedicated OHS personnel operate under the ISO 45001 framework, responsible for planning, implementation, supervision, and auditing to ensure the system's effective operation.

Occupational Health and Safety Education and Training

Safety and Health Performance Indicators

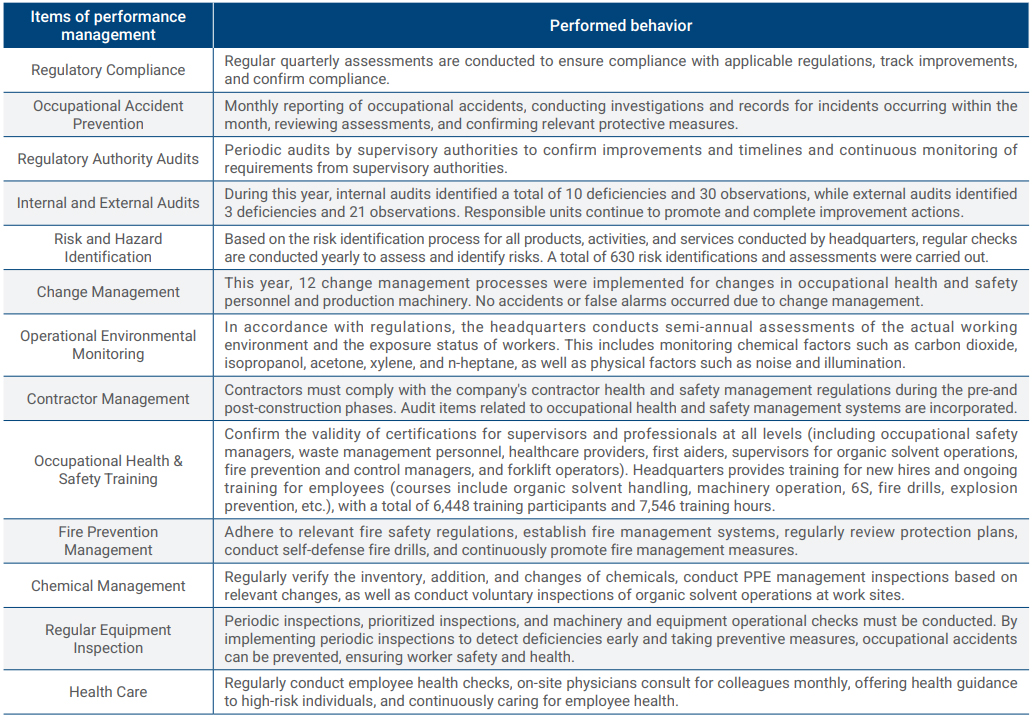

Occupational Hazard Identification and Risk Assessment

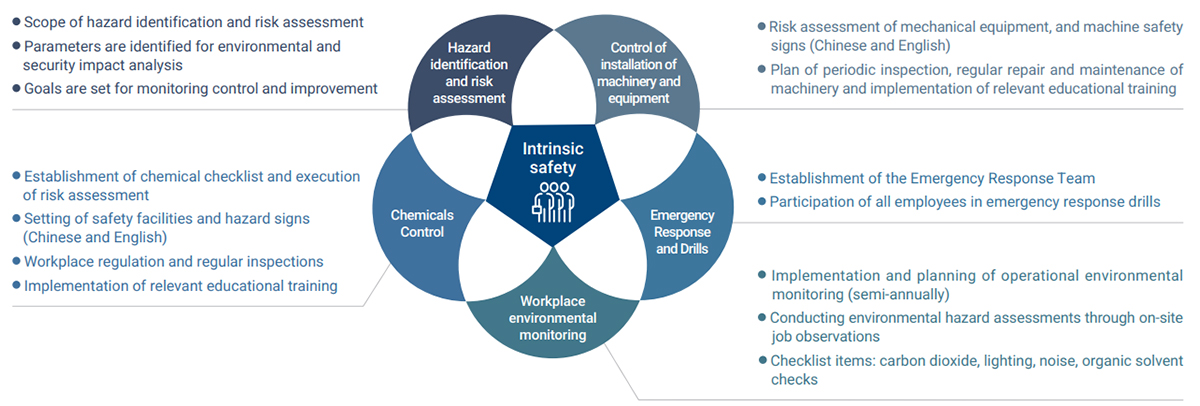

To prevent occupational accidents, the Company has established a procedure for identifying environmental aspects and occupational health and safety risks and opportunities. This procedure evaluates the hazards and risks that operational activities may pose to employees, stakeholders, or the workplace, identifying risks that need to be controlled and opportunities for improvement. Based on the identified parameters, an occupational safety and health impact analysis is carried out, Based on the results of the risk identification and assessment, prioritize the risk and identify those requiring action plans, feasible and optimal control measures are determined in the following order: elimination, substitution, engineering control, administrative control, and personal protective equipment. Management plans and quantified targets are formulated to implement monitoring, control, and improvement.

We have identified high-risk work environments, such as those involving hazardous chemicals, excessive noise, and ionizing radiation. For personnel operating in these environments, we provide appropriate personal protective equipment and conduct regular specialized health check-ups to monitor and safeguard their well-being. Regarding potential hazards and risks in the workplace, we also comply with Article 18 of the Occupational Safety and Health Act and Article 25 of the Enforcement Rules of the Occupational Safety and Health Act concerning the criteria for "potential imminent danger". Employees are informed that if they encounter a situation posing an imminent danger during work, they may, without penalty, evacuate to a safe location after reporting the danger immediately. This policy further reinforces our commitment to ensuring employee safety and health.

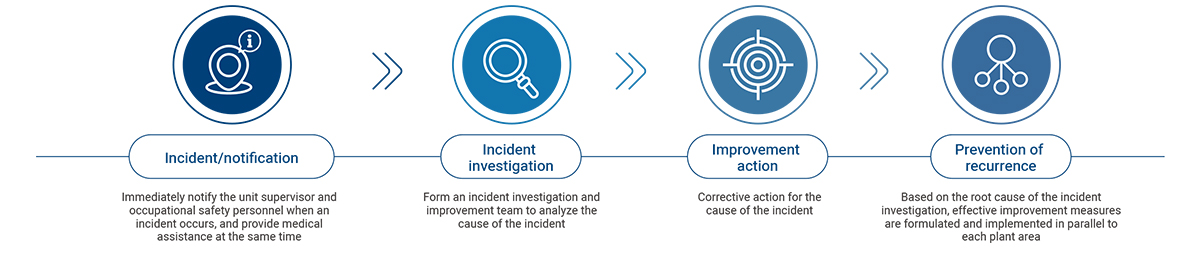

Incident notification and investigation procedures

Advantech strives to achieve the safety goal of "zero accidents in the workplace" and has established the "Job accident investigation and treating SOP" to regulate relevant procedures such as incident reporting, accident investigation responsibilities, subsequent improvement actions, and preventing similar accidents from occurring again.

Disabling injury statistics analysis

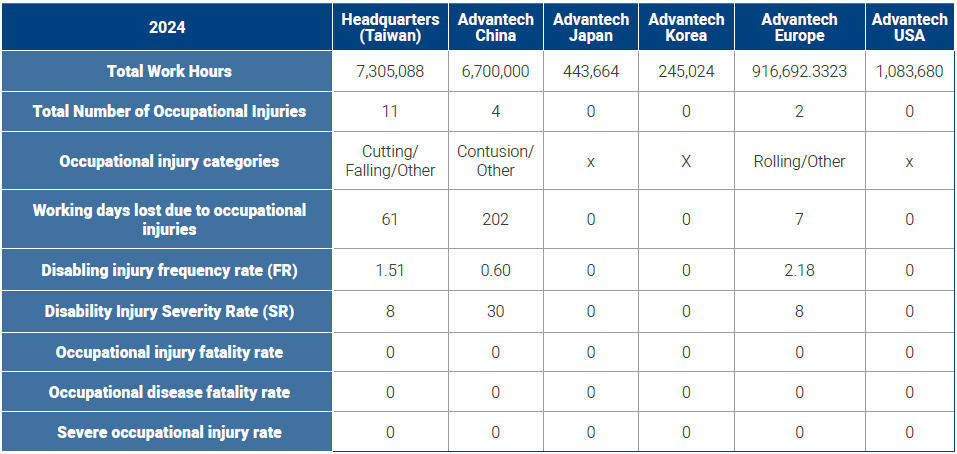

Advantech Employee Occupational Injury Statistics

1. Total working hours (headquarters) = Total working hours are based on monthly reports from OSHA, MOL.

2. Other regions/total working hours = Number of people in each region x number of workdays per year x number of hours worked per day

3. FR = (Total number of injury losses × 1,000,000) ÷ Total hours worked (rounded to two decimal places)

4. SR = (Total number of lost workdays due to injury × 1,000,000) ÷ Total hours worked (disregarding decimal places)

5. Occupational injury fatality rate = Number of fatal occupational injuries ÷ Total number of occupational injuries

6. Occupational disease fatality rate = Number of occupational diseaserelated fatalities ÷ Number of occupational disease cases

7. Occupational diseases: Certified by occupational medicine physicians, local labor competent authorities, or OSHA, MOL.

8. Occupational Injury Absenteeism Rate = (Total Number of Absenteeism Days Due to Occupational Injury/Total Number of Workdays) x 100%

9. Serious occupational injury rate (AR) = Injuries where workers are unable to recover to their pre-injury health status within six months, excluding fatalities.

10. The above data excludes commuting accidents.

11. The end date for headcount statistics is December 31, 2024.

Non-Advantech employee occupational injury statistics

(1) Non-Advantech employees: Security personnel, janitors, caterers, and temporary workers.

(2) Total working hours (headquarters) = Total working hours are based on monthly reports from OSHA, MOL.

(3) Other regions/total working hours = Number of people in each region x number of workdays per year x number of hours worked per day

(4) Occupational injury absentee rate = (Total absent days [injury leave]/total person-days) x 100%

(5) Serious occupational injury rate (AR) = Injuries where workers are unable to recover to their pre-injury health status within six months, excluding fatalities.

(6) Occupational diseases: Certified by occupational medicine physicians, local labor competent authorities, or OSHA, MOL.

(7) The headcount statistics are up to December 31, 2024.

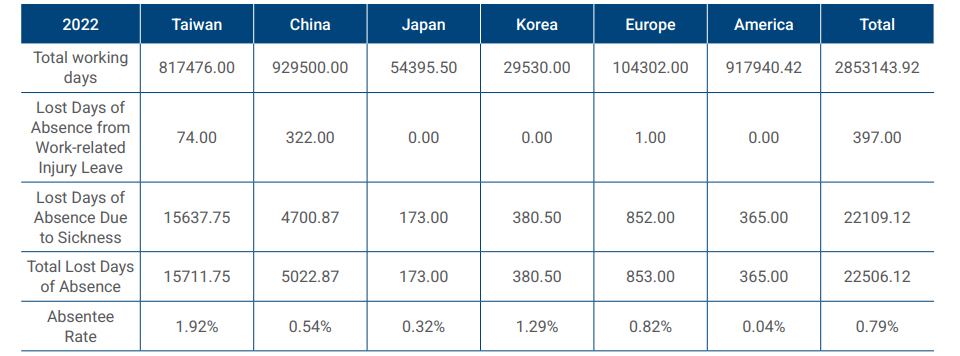

Employee Absentee Rate Statistics

(1) Absentee rate calculation: (Total days of absence [official injury leave + unpaid sick leave]/total work days) x 100%

(2) Employee absentee rate calculations do not include pre-planned or approved leave, such as personal leave, annual leave, maternity leave, paternity leave, and official leave.

Occupational health and safety committee

Health Management: Building a Workplace that supports employee well-being

In today's fast-changing workplace, businesses' care for employees has shifted from traditional remuneration and benefits to a more holistic approach focused on health management and overall well-being. Employees' physical and mental health not only affects their job performance but also has a direct impact on the Company’s overall operations and long-term development. Ensuring employees' well-being goes beyond providing basic healthcare; it also encompasses mental health, work-life balance, as well as the care and support reflected in a company's corporate culture.

This not only enhances employees' sense of well-being and loyalty but also reduces absentee rate and turnover, while boosting work efficiency and innovation. Therefore, integrating health management and employee well-being is a key aspect of corporate sustainability development. In particular, activities for mature-aged employees are organized according to OSHA's guidelines on the safety and health of middle-aged and older workers, providing a more supportive workplace.