Vision and Promise

In response to UNDP’s SDG 9 (industry, innovation, and infrastructure) and SDG 12 (responsible consumption and production), Advantech has established various eco design goals pertaining to raw materials, product design, manufacturing, and environmental management. We have introduced various standards aimed at improving the environment, minimizing environmental impacts from operations.

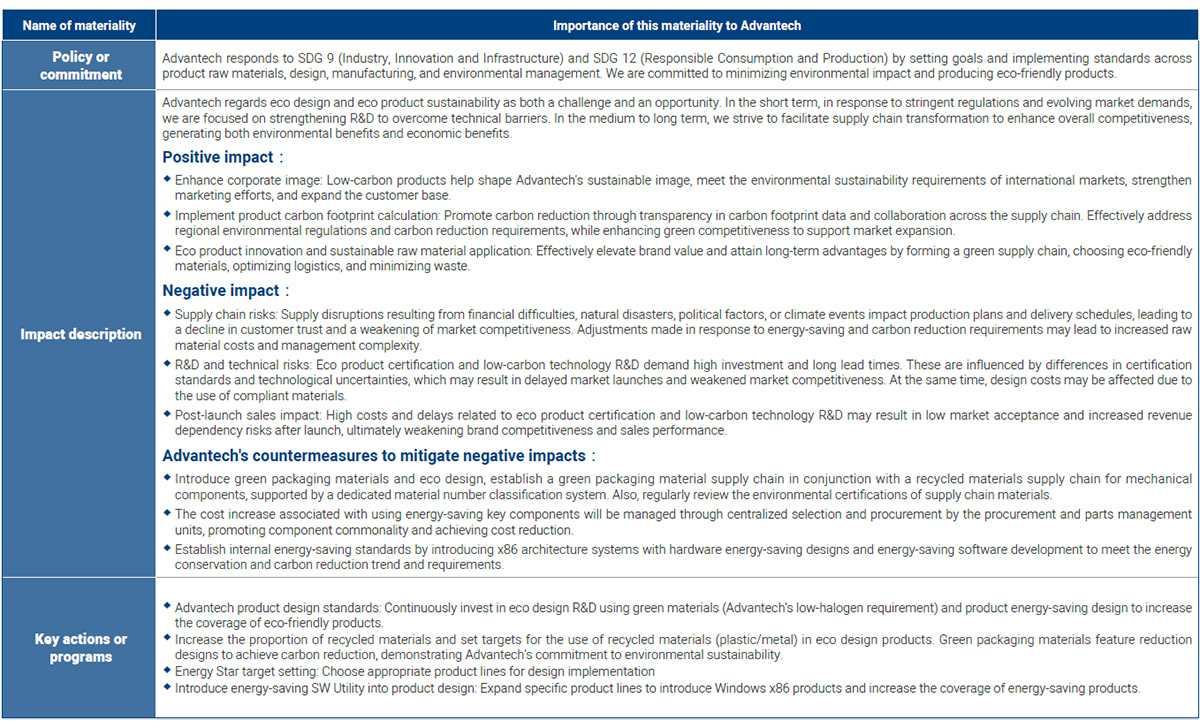

Management Guidelines for Major Topics/Management Structure

Phased Achievements and Future Goals of Eco Design

Annual initiatives, performances, and future goals

-

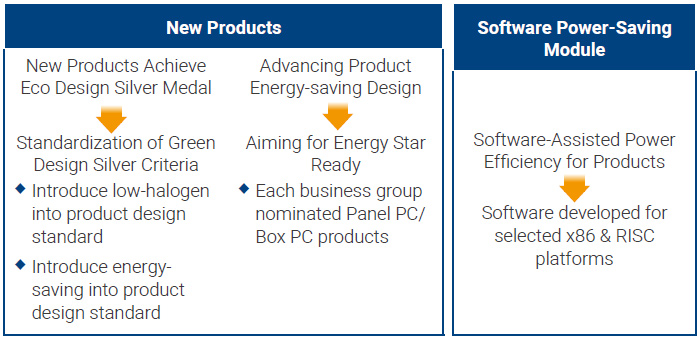

- Advantech's silver medal for green eco design guidelines was introduced to form internal regulations

- Advantech has established internal regulations for energy-saving design and eco materials (Advantech's lowhalogen requirements) to effectively increase the coverage rate of Advantech's green eco design products.

-

- Energy Star goal setting

- Introduce Energy Star energy-saving design requirements for specific product lines and obtain the internal energy-saving Gold medal.

-

- Development of energy saving SW Utility

- By using energy-saving software to support hardware energy efficiency, introduce it into new x86 Windows specific product line models

-

- Re-optimization of green eco design products

- Continue to standardize the silver medal for green eco design products into a mandatory requirement for new Advantech models, and actively design and develop Advantech gold medal models compliant with green eco design products.

2024 performance

-

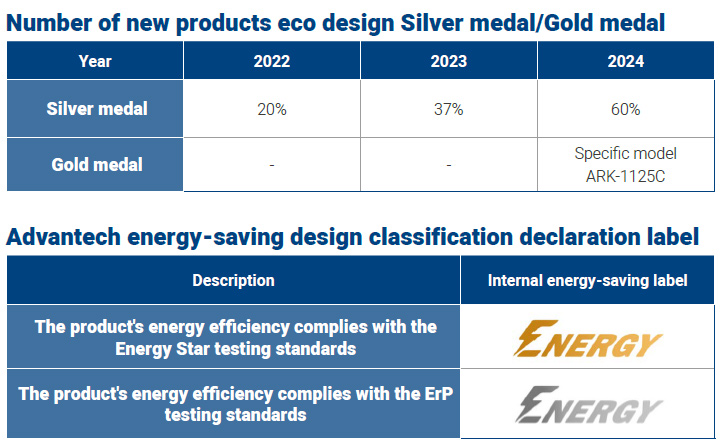

- 60% new product percentage

- The percentage of eco design system category products achieving the internal self-declared Silver medal certification

-

- 90% achievement rate

- Products under 5kg use molded pulp packaging instead of EPE Achievement rate

-

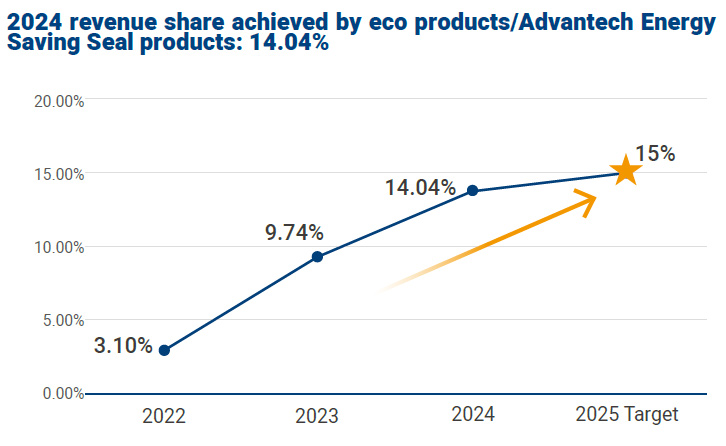

- 14.04% revenue share

- The revenue share of mass-produced products achieving eco design product Silver medal / Advantech Energy Saving Seal for the entire year.

-

- 91.2 %

- Percentage of Advantech Low Halogen mechanical plastic parts used in products sold for the year

Eco Design

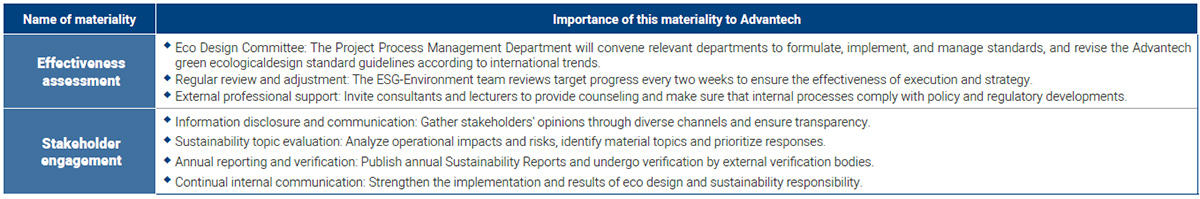

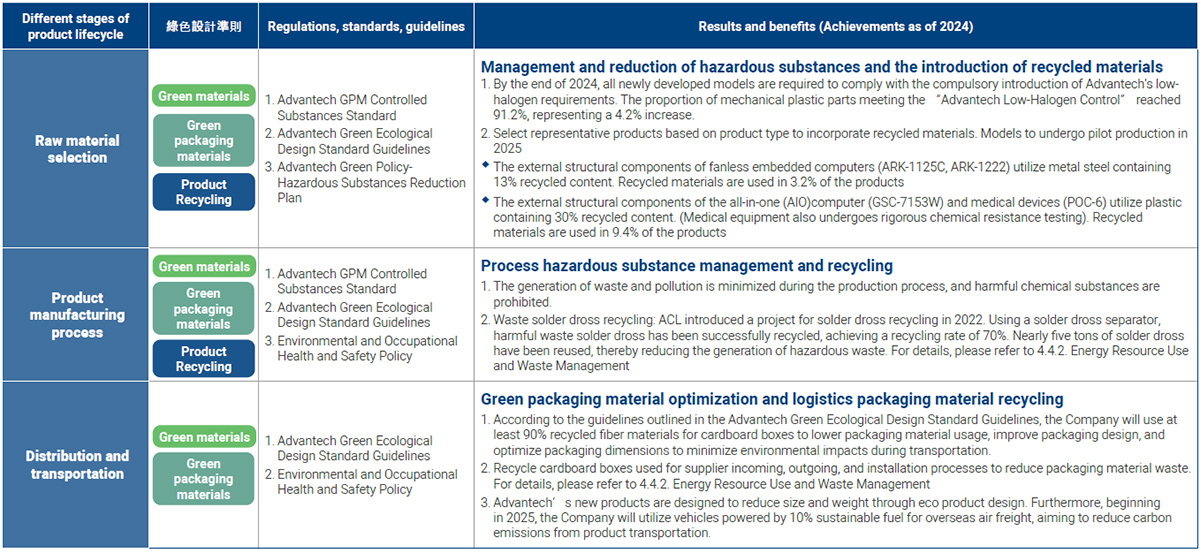

Eco-Product following the LCA life cycle

Advantech follows the concept of product lifecycle, using life-cycle assessment (LCA) and product carbon footprint to quantify the environmental impact analysis of Advantech products. The assessment covers carbon emissions across all stages, including raw material selection, manufacturing, transportation, usage, and final disposal. The Company will establish carbon reduction targets and implement corresponding actions, integrating these goals into its overall operational management strategy.

In addition, Advantech has established eco product design management and standard guidelines, integrated into the product lifecycle process to guide Product Departments in creating eco-friendly and innovative products.

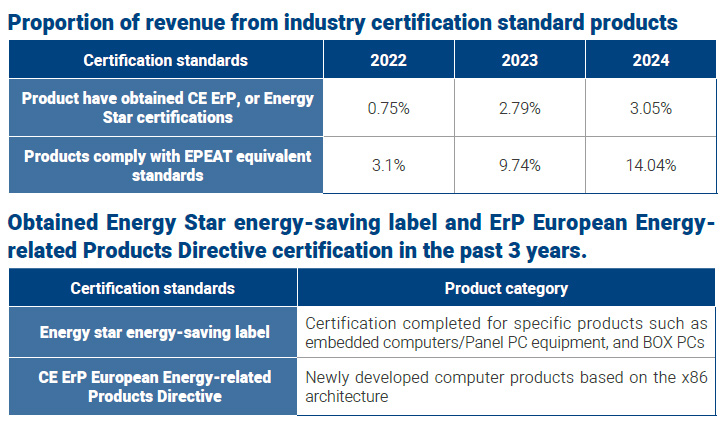

Eco product design management and standards formulation

Advantech’s standards are grounded in international environmental regulations and assessment tools, such as the U.S. Electronic Product Environmental Assessment Tool (EPEAT). These standards focus on four major aspects of products: (1) green materials, (2) green packaging materials, (3) product recycling, and (4) product energy saving. Environmental impacts are evaluated at different stages of the product lifecycle. Drawing on extensive experience in regulatory compliance and collaboration with global brand customers, Advantech has established the Green Ecological Design Standard Guidelines to enhance energy efficiency, promote ecological design, and reduce environmental toxicity and hazards.

Advantech develops intelligent product carbon footprint solution to comprehensively manage product carbon footprint.

Amidst the global net zero and carbon neutral trend, the industrial PC industry must not only provide high-performance, low-power solutions but also actively implement carbon reduction measures to meet the sustainability requirements of customers, investors, and the international market. With the implementation of the EU's Carbon Border Adjustment Mechanism (CBAM), national carbon disclosure policies, and growing emphasis from major multinational corporations, transparency in carbon footprint disclosure has become a key factor in maintaining international competitiveness.

In light of this, Advantech launched a product carbon footprint inventory project in 2023 and, in the same year, obtained the first ISO 14067 verification for an integrated computer product's carbon footprint. Through product life-cycle assessment (LCA), we evaluated the depth of material selection and identified the top five key materials contributing to the carbon footprint. Additionally, in the same year, we completed the establishment of Advantech's product carbon footprint inventory methodology, laying the foundation for the internal development of product LCA. Starting in 2024, we successively completed carbon footprint inventories for representative products across various business units and initiated the construction of Advantech's internal Product Carbon Footprint Intelligence Platform, creating our intelligent solution for product carbon footprint calculation, which is applied to eco product design projects.

Advantech is actively developing a product carbon footprint calculation system, which will not only help determine the carbon footprint of each product on the market but also promote carbon pricing and product carbon footprint reduction strategies. This system adopts the LCA methodology, referencing international standards such as ISO14040, ISO 14067, and the GHG Protocol. By integrating Advantech's internal raw material, supplier information, and production management systems with external APIs, and incorporating AI technology to build a carbon footprint factors database for each raw material, the system can rapidly calculate product carbon footprint and generate carbon footprint reports. This allows for the evaluation of emissions during various stages of the product lifecycle. It is expected that the calculation of all products sold in 2024 will be completed by 2025, accounting for about 100% of the total revenue.

This system not only simplifies the complex manual calculation process but also enables Advantech to quickly identify product emission hotspots, laying a solid foundation for future reduction efforts. Through this system, Advantech can not only actively adjust design and production strategies by identifying products with high carbon emission risk in advance but also offer customers the necessary product carbon footprint information to meet global customer demands, further strengthening Advantech's leadership position in sustainability.

Product Liability

Advantech integrates eco design and circular design principles into the product lifecycle during the development process, emphasizing strategies, goals, and directions. The Company is committed to continuing to research and develop innovative eco products and solutions, delivering high-efficiency, reliable energy-saving integrated solutions and services, while minimizing waste generation at the source of design. We will continue to uphold the eco design philosophy by implementing strategies such as low-carbon material selection, product lifespan extension, and value enhancement. Our products will be free of hazardous substances, easy to disassemble and recycle, and designed to increase the use of recycled materials. Through these efforts, we actively practice the principles of Reduce, Reuse, and Recycle, promote corporate producer responsibility, and support the achievement of SDGs.

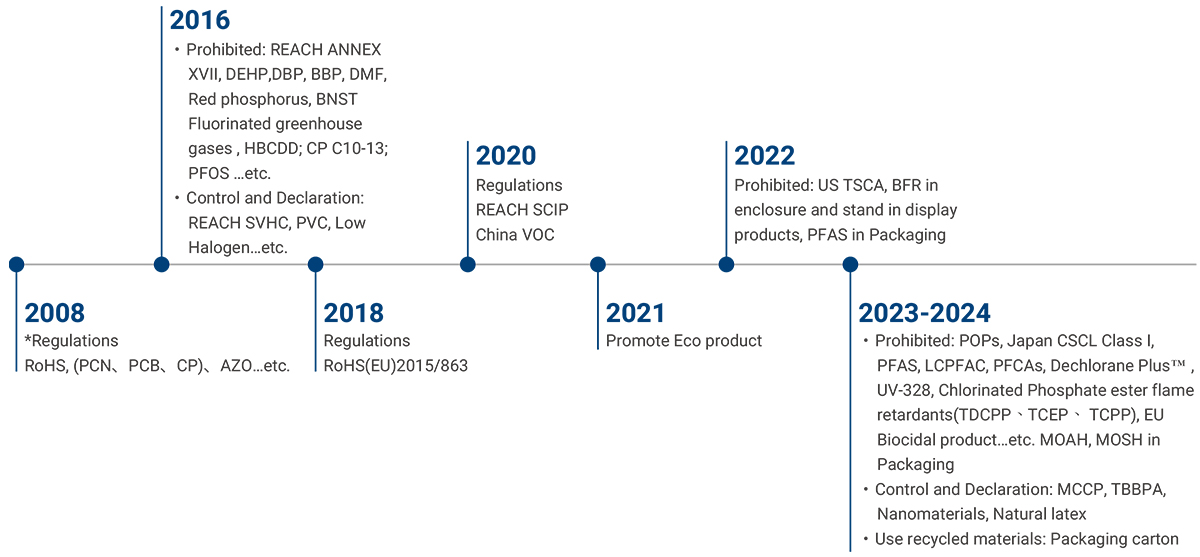

To mitigate the negative environmental and social impact of raw material use, Advantech has established the “Hazardous Substances Reduction Plan” and the “Sustainable Raw Materials Management Policy” to implement sustainable procurement and optimize supply chain management efficiency, further contributing to the realization of the net zero by 2025 target. In line with this policy, we prioritize the use of raw materials with minimal environmental and social impact across all business activities, including R&D, procurement, production, operations, and services.

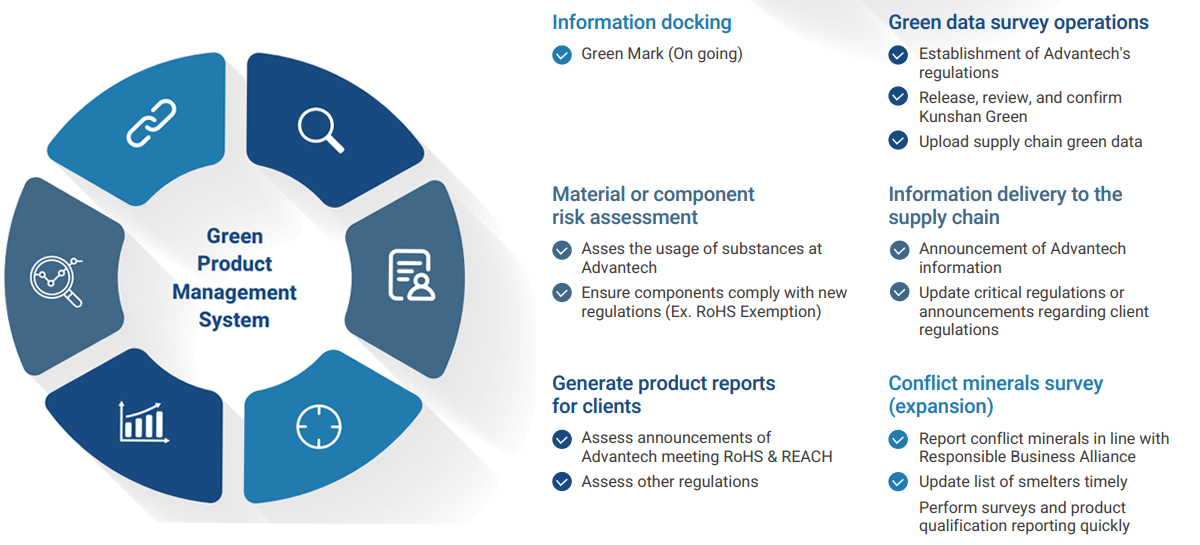

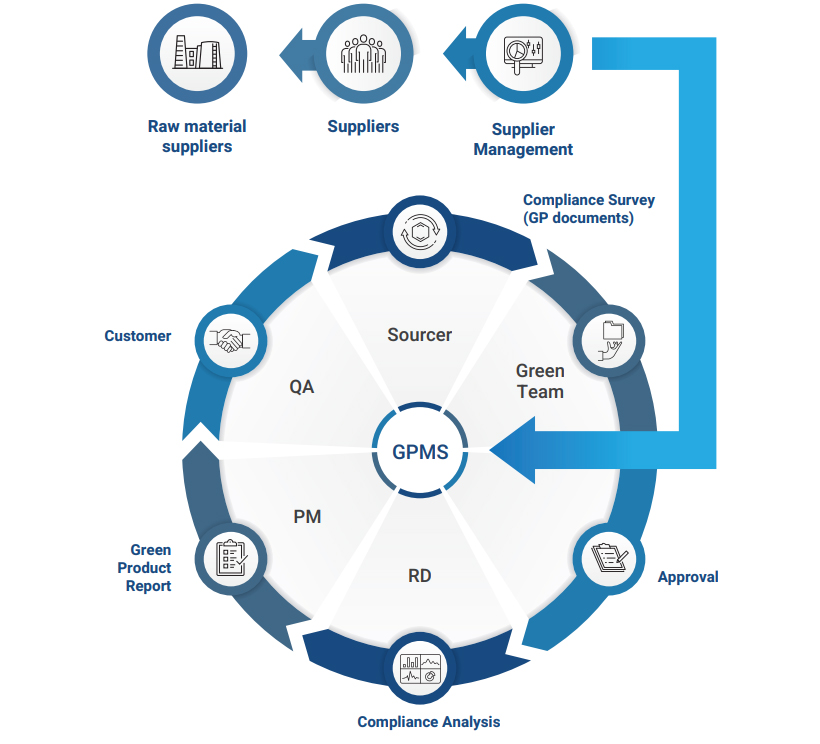

Green Supply Chain Management Platform GPMS

Green Supply Chain Management Process

Advantech’s Green Policy - Hazardous Substance Reduction Program

Sustainable raw material management

As part of Advantech's raw material procurement strategy, we conduct sustainability risk assessments, in addition to cost-benefit considerations, to determine procurement priorities and ensure the effective implementation of sustainable management. We collaborate with suppliers to increase the transparency of raw material sources, assess the potential environmental and social impacts of their development and production processes, and select the most appropriate raw materials for Advantech based on the outcome of supplier sustainability risk assessments.

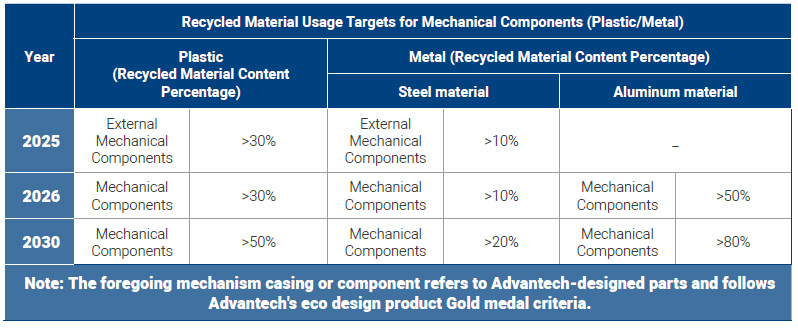

In the third quarter of 2024, Advantech launched the sustainable raw material project to evaluate the use of recycled materials by tracing the source of raw materials. Moreover, recycled materials were introduced to major business groups to conduct the pilot production plan. The project extends into the first quarter of 2025, and it has successfully achieved its phase goals, including compiling statistics on raw material traceability, evaluating the effectiveness of trial integration of recycled materials into product structural components, and drafting preliminary targets for future implementation. In terms of raw material traceability, considering the characteristics of Advantech's products, we prioritize the top three raw materials by usage volume for implementing control: plastics, steel/iron, and aluminum. These three recycled materials were introduced to the sustainable raw materials pilot program. Furthermore, in addition to managing product structural components, we also conducted a traceability survey for packaging materials. Currently, the implementation outcomes of recycled material usage ratios, categorized by product type, are detailed in Figure.

Green packaging materials

To make tangible contributions toward biodiversity, deforestation prevention, and land preservation, Advantech requires key packaging material suppliers to obtain FSC ™ CoC (Forest Stewardship Council Chain of Custody) certification. As of 2024, we have successfully applied FSC ™ certified paper materials to the packaging cardboard boxes of one Network model.

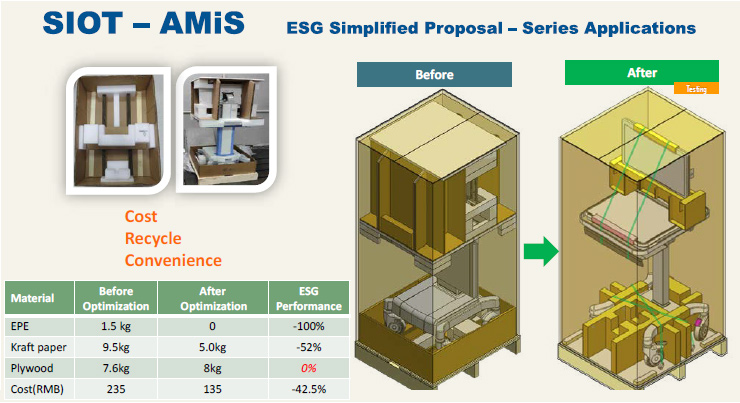

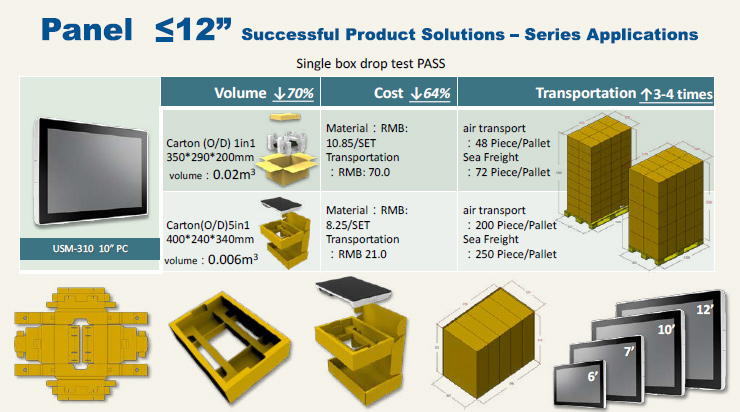

Since 2023, the product packaging design team has actively optimized green packaging by adopting honeycomb design dividers to replace traditional EPE cushioning materials and increasing the proportion of recycled materials used. At present, our packaging materials contain over 90% recycled fibers, achieving 100% of the target. For packaging materials of products weighing 5kg or less, molded pulp is used to replace EPE. The achievement rate reached 90% in 2024.

Product energy saving

Key strategies are implemented on hardware and software to improve energy efficiency, decrease energy consumption, and extend product lifespan.

Hardware: Continuing previous energy-saving targets, design internal regulation standards were officially adopted in new standard products with X86 architecture in 2024. Cer tain products are designed in alignment with Energy Star standards standard, serving as benchmark models that deliver greater carbon reduction benefits and progressively enhance overall emission reduction performance.

Software: Starting in 2024, the EIoT Software and Hardware Team vigorously researched and developed energy-saving features for software modules, successfully implementing them in the Power Suite software module. Through BIOS energy-saving detection suggestions, OS energy-saving settings, and optimized power management, equipment energy consumption was lowered effectively. The introduction of model trial runs was completed for the X86 system product AIR-150 and the RISC platform EPC-R3720. Fur thermore, a standardized energy consumption testing mechanism was developed to ensure the software energy-saving effectiveness. In maximum energy-saving mode, carbon emissions can be reduced by 242.4 tons annually. In 2025, this feature is expected to be introduced to new specific product lines, including Windows x86 products, significantly expanding the coverage of energy-saving solutions.

Responsibility for Product End-of-Life : Product Recycling

By incorporating design considerations for easy recycling from the initial product design phase, such as “recyclability, ease of disassembly, low pollution, and energy saving,” Advantech has set a target recycling rate of 90% for its eco design products. Adhering to the principle of producer responsibility, we are committed to e-waste recycling management and, through legally required recycling programs, aim to promote the reuse and circularity of electronic products. The calculation of the proportion of recyclable products was carried out based on product category and inventory, and the average reached nearly 97% in 2024, an increase of 3% compared to last year. This is higher than the WEEE directive requirements.

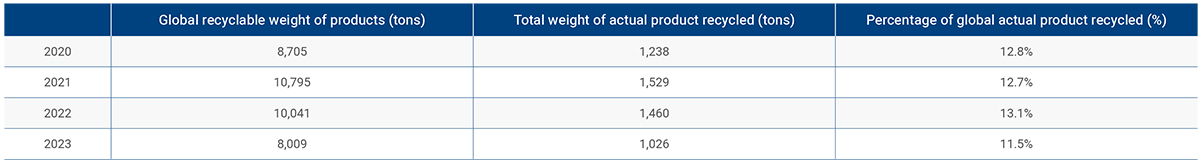

Comply with local waste recycling laws and regulations in various countries, including Europe, the United States, Japan, Korea, Taiwan, and Kunshan. According to Global Transboundary E-waste Flows Monitor 2022 and 2024, the global e-waste reached 62 million tons, and the recycling rate was only 22.3%. In particular, the recycling rates for Asia, the United States, and Europe are 12%, 30%, and 42.8%, respectively. By utilizing these regional recycling rates, the percentage of global actual product recycled can be estimated, providing a basis for calculating realistic recycling data.