Management Guidelines for Major Topics

Greenhouse Gas (GHG) Inventory and Energy Management

Adheres to the original devotion to the idea of being a global citizen. Advantech has completed third-party verification since 2019, in addition to the self-assessment required by ISO 14064-1:2018 and the GHG Protocol. In recent years, we have continued to implement GHG management based on the results of our annual inventory checks. We have also made efforts in product design, product material management, product energy efficiency improvement, and renewable energy use. Starting in 2023, other overseas significant locations of operation engaged in GHG inventory and verification. In the same year, Advantech joined the RE100 initiative, committing to 100% renewable energy by 2040. Currently, our sites in Kunshan, Europe, and the United States are already using renewable energy. This chapter's writing scope covers Advantech's main global operations and production factories, together accounting for 92.6% of total consolidated revenue.

Highlighted Projects

Greenhouse Gas Inventory and Management

In order to create a low-carbon emission business environment, Advantech has established the “Greenhouse Gas Inventory Promotion Committee” based on the quantification, monitoring, reporting, and verification procedures for GHG inventory provided by Taiwan's Climate Change Response Act and the ISO 14064-1 standards to promote GHG inventory and reduction work in order to reduce direct and indirect GHG emissions year by year. And joined the Carbon Disclosure Project (CDP) since 2015 to disclose the Company's carbon reduction plans and performance annually.

Greenhouse Gas Inventory

Beginning in 2024, except for Taiwan and the Kunshan plant, China, Advantech has progressively conducted GHG inventory at its overseas significant locations of operation and production sites. Two new sites, AJMC (Japan) and AKSC (Korea), were included in 2024. In the future, other overseas significant locations of operation and production sites will also be incorporated.

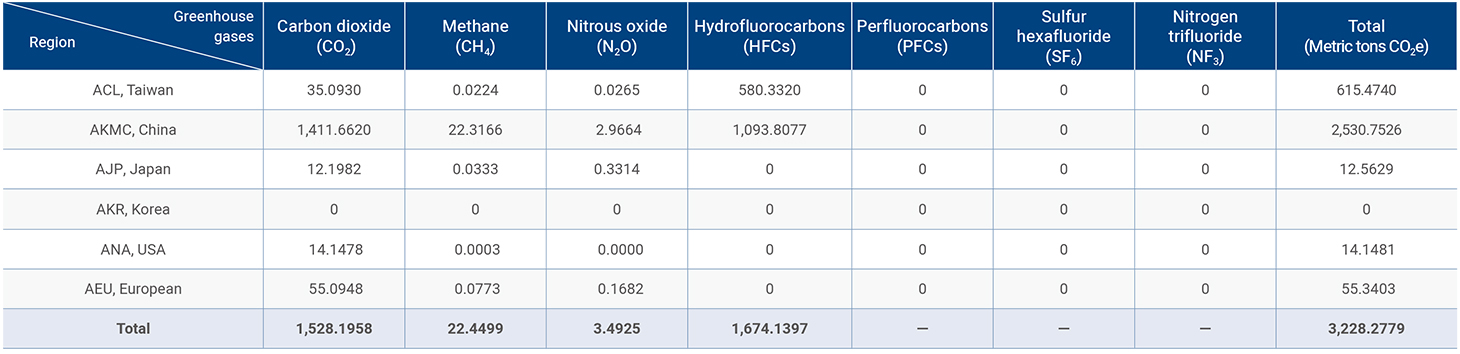

Since 2019, ACL has conducted self-verification according to ISO 14064-1 and the GHG Protocol, and has also undergone third-party on-site verification. The organizational boundary is defined based on operational control, in accordance with the requirements of ISO 14064-1:2018. The inventory scope includes both qualitative and quantitative assessments of Scope 1 (category 1: direct GHG emissions) and Scope 2 (category 2: indirect GHG emissions from energy), and also covers emission sources under Scope 3 (categories 3, 4, and 5: indirect GHG emissions). In 2024, the total emission of Scope 1 emissions from ACL was 804.39 metric tons of CO₂e. The 2024 inventory results for Advantech's Kunshan plant indicate that Scope 1 emissions were 2,531.42 metric tons of CO₂e, and this has been verified by a third party. Also, since 2024, Advantech has included AJMC (Japan) and AKSC (Korea) sites in the scope of ISO 14064-1 GHG inventory and verification for the first time. The Scope 1 emissions for the two sites were 150.32 and 9.77 metric tons of CO₂e, respectively. In addition, the United States and European sites continue to conduct GHG inventories for Scope 1 energy use, and starting in 2025, Advantech plans to progressively complete a comprehensive group-wide Scope 1 and Scope 2 inventory, accompanied by third-party verification. Emissions in each region are shown in Table .

Scope 1 GHG emissions by Advantech's Main Global Operations and Production Factories in 2024

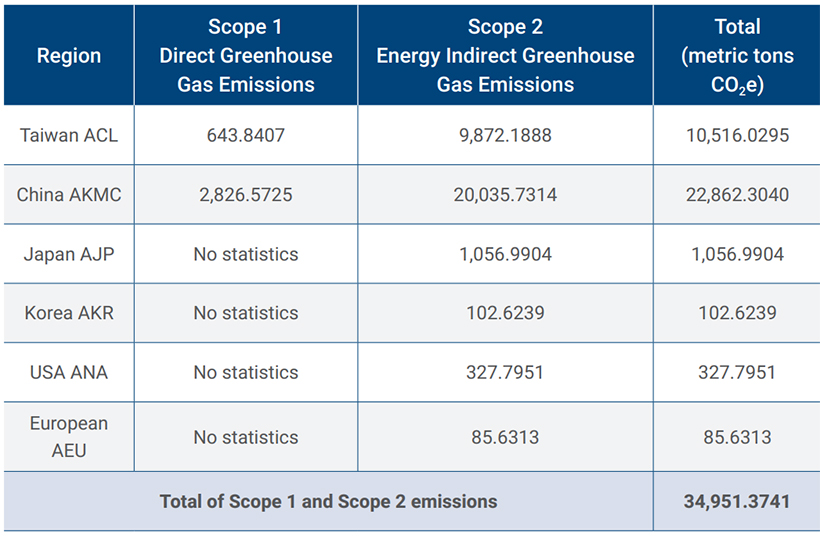

Among Advantech's Taiwan factories (ACL), Scope 2 emissions are solely from purchased electricity. The carbon emissions are calculated using the 2023 Electricity Carbon Emission Factor of 0.494 kg CO₂e announced by the Bureau of Energy, Ministry of Economic Affairs, totaling 9,222.26 metric tons of CO₂e. For Advantech's Kunshan sites(AKMC), Scope 2 emissions include the use of purchased electricity and purchased steam, totaling 11,974.12 metric tons of CO₂e (Market-based). The electricity carbon emissions are calculated using the average national electricity carbon emission factor for 2022 (excluding non-fossil energy electricity from market-based transactions) of 0.5856kg CO₂/kWh, as stated in Table 4 of the “Announcement on the Electricity Carbon Emission Factor for 2022”. The carbon emissions from steam are calculated using the emission factor for steam of 110 kg CO₂/ GJ, as referenced in the “GHG Emission Accounting and Reporting Guidelines for Industrial and Other Sectors.” In addition, AJP, AKR, ANA, AEU Scope 2 use purchased electricity only. Among these, AJP uses the electricity carbon emission factor of 0.4060 kg CO₂e/kWh provided by the manufacturer, Kyushu Electric Power; AKR and ANA use the nationally announced electricity carbon emission factors of 0.4781 kg CO₂e/kWh and 0.2075 kg CO₂e/kWh, respectively; and AEU's electricity carbon emission factor is 0 kg CO₂e/kWh as it uses 100% renewable energy.

The Scope 1 and Scope 2 GHG emissions for Advantech's main operation and production sites are shown in Table 4.3.2. In 2024, the total combined emissions for Scope 1 and Scope 2 were 26,296.8217 metric tons of CO₂e (Market-based). Figure 4.3.2 shows the amount of Scope 1 and Scope 2 GHG emissions by Advantech's main operation and production plants in recent years.

Scope 1 and Scope 2 GHG emissions by Advantech's Main Global Operations and Production Factories in 2024

1. The GHG inventory check of ANA, AEU has not been verified by third party.

2. In the market-based calculation, the GHG emissions from renewable energy sources in AKMC, AEU and ANA were calculated with the electricity emission factor as 0.

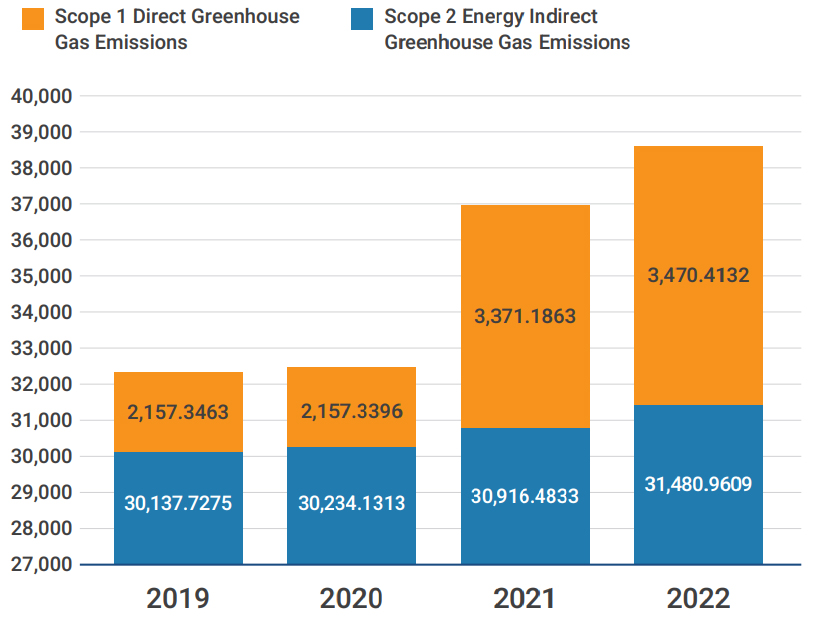

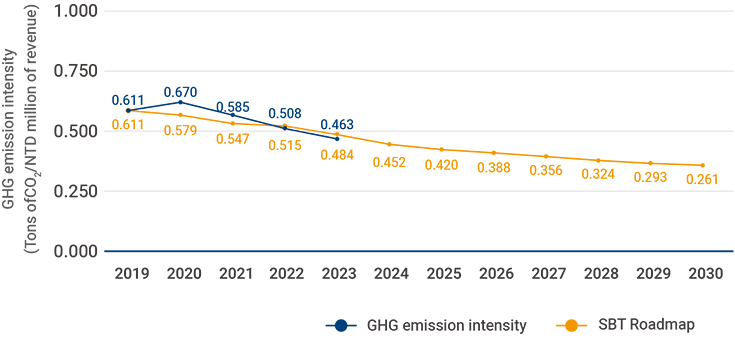

In 2023, the average amount of GHG emissions per unit of revenue (Scope 1 and Scope 2) of Advantech's main operating locations and production factories was 0.463 tons CO₂e/NT$ million revenue, reduced by 24.3% and 9.0% respectively compared with 2019 and 2022, and continue to move towards the SBT goal of 60% reduction by 2030, as shown in Figure 4.3.2. In 2023, in addition to establishing an energy management policy and adopting the ISO 50001 energy management system, Advantech uses its iEMS intelligent energy management platform to monitor energy consumption in real time, optimize equipment operation and improve power consumption efficiency. It also holds energy project meetings regularly. We share and interact to continuously improve energy efficiency. In the future, we will continue to set the goal of GHG reduction per unit of sales per year. In addition to achieving the goals set by the SBT announcement, this will also deeply embed the concept of energy saving in the hearts of colleagues and help it become an important part of the Company's culture.

Advantech's direct and indirect energy greenhouse gas emissions in recent years

*Note 2: In 2024, the regions using renewable energy included AKMC, AEU, and ANA. AKMC utilized Green Energy Certificates (GEC); AEU sourced 100% renewable energy directly from supplier; and ANA partially used electricity generated by its solar power system.

In 2024, the average GHG emissions (Scope 1 and Scope 2) per unit of revenue for Advantech's main global operations and production sites were 0.440 metric tons of CO₂e per NTD million, representing a decrease of 28.0% and 4.9% compared to the average GHG emissions per unit of revenue in 2019 and 2023, respectively. This demonstrates our continued progress towards the 2030 SBT of a 60% reduction, as shown in Figure.

In 2024, Advantech not only continued to manage and optimize its energy usage efficiency by following its energy management policy, the ISO 50001 energy management system, and iEMS, but also promoted experience sharing among its facilities, continuously improving energy usage efficiency through regular energy project meetings.

Looking ahead, we will continue to achieve our RE100 and carbon reduction goals through a combination of employee training, carbon reduction and energy-saving projects, energy target setting, increased adoption of renewable energy, setting more ambitious SBT targets aligned with the 1.5 ° C pathway, and the establishment of internal carbon pricing. Furthermore, we also committed to incorporating energysaving and carbon reduction principles into our corporate culture, encouraging all employees to work together toward a net-zero and sustainable future.

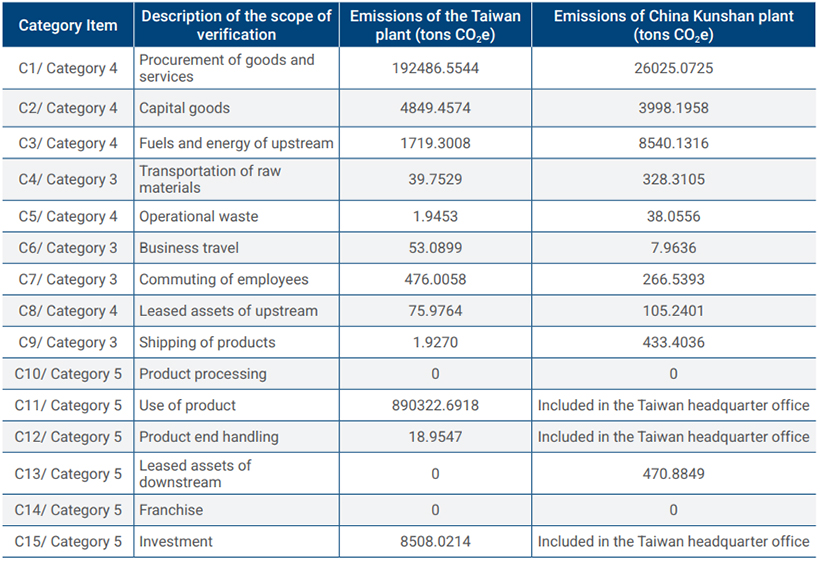

Scope 3 identification and emissions of greenhouse gases from Advantech Taiwan and Kunshan factories

1. Scope 3 C1-C15 correspond to ISO14064-1:2018 Categories 3-6

2. The use of products and the disposal of products are the scope of the global inspection of Advantech.

Advantech's Scope 3 emissions statistics over the years

Energy Data Management

The main source of GHG emissions from Advantech's factories is CO₂ emissions from the generation of purchased electricity necessary for the Company's operations, which accounted for over 80% of the Company's overall emissions in 2024. In 2024, the overall energy consumption (including electricity, steam, gasoline, diesel, and natural gas) at Advantech’s main operating locations and production sites was 197,853.39 GJ, with purchased electricity accounting for 95.92% of total energy consumption (including 9.46% from renewable energy sources), representing a 1.78% reduction compared to 2023.

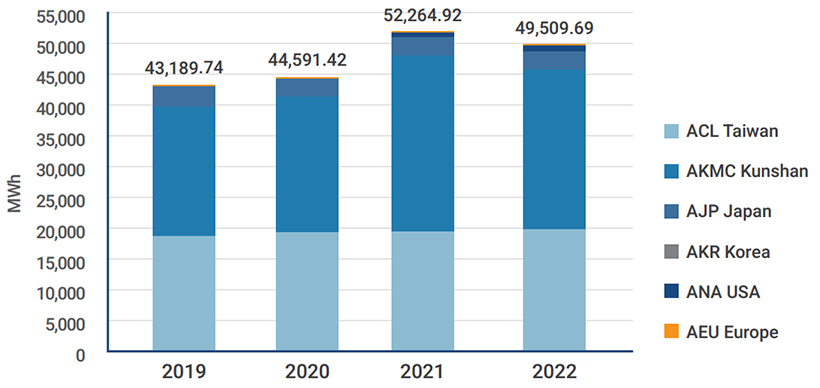

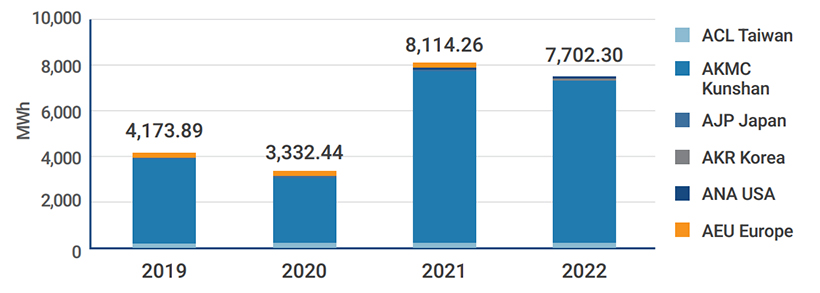

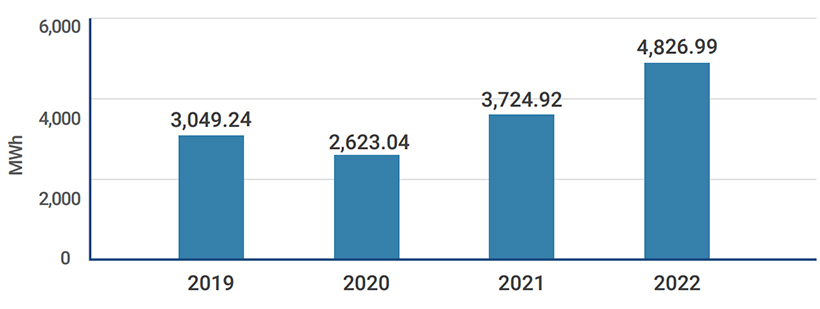

Advantech factory electricity consumption statistics

Non-renewable Fuels Consumption among Advantech‘s Main Operations and Production Factories in Recent Years (diesel, gasoline, natural gas, LPG)

Non-renewable energy consumption(purchased steam) by Advantech’s main operating locations and production plants in recently years.

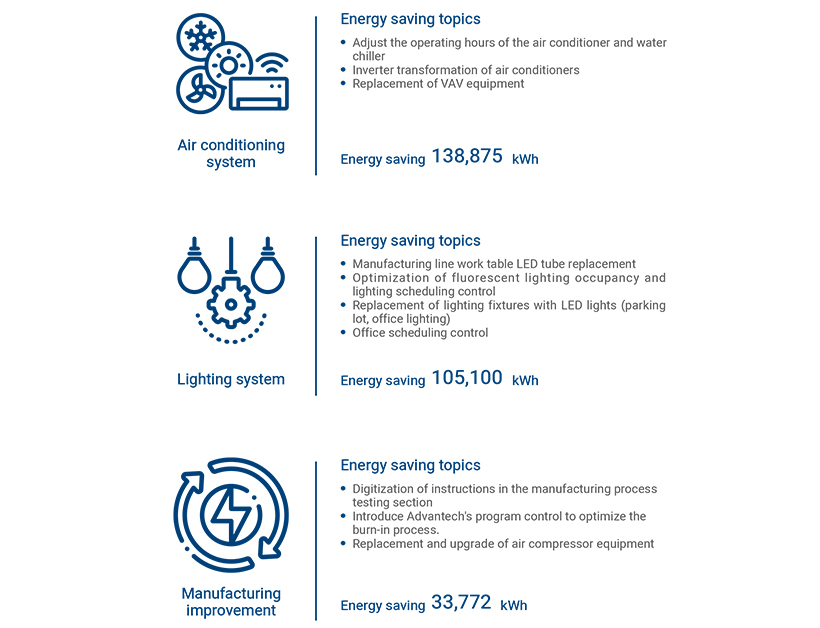

Energy Management Action

Electricity is Advantech's main energy source. To minimize the environmental impact of its products and production activities, Advantech has established an Energy Management Policy and implemented the ISO 50001 energy management system at its significant locations of operation in Taiwan and Kunshan, China, to systematically manage energy reviews, energy-saving solutions, and benefit analysis processes. Meanwhile, Advantech has established an intelligent energy management system (iEMS) that can monitor energy consumption in real-time, identify energy hotspots, and optimize equipment operation to improve electricity usage efficiency. Additionally, Advantech has established clear energy-saving indicators and targets, and the energy management unit regularly convenes project meetings to monitor implementation progress to continuously increase energy usage efficiency and the percentage of renewable energy used. Furthermore, in 2024, Advantech also monitored electricity consumption management indicators across its six global RBUs to further standardize and improve electricity management in its various operations. At the same time, we continue to launch global renewable energy initiatives, enhance the procurement and usage of renewable energy, and collaborate with all locations of operation to achieve RE100 goals and sustainable energy management.

In terms of energy management strategy, Advantech adopts a three-stage approach of energy saving, energy generation, and energy procurement to continue reinforcing energy management, optimizing resource allocation, and gradually achieving the goals of sustainable energy management and renewable energy transition.

Energy Efficiency Management Mechanism

Advantech has established an internal energy management mechanism and introduced the ISO 50001 Energy management systems. Through the effective operation of the management system, Advantech implements source management from the procurement side, evaluates the organization's energy consumption through energy review, and identifies energy consumption hot spots. This is combined with the self-developed iEMS. We implement real-time monitoring using the system’s energy dashboard to manage major energy-consuming equipment to ensure optimal energy efficiency. We also formulate energy-saving solution benefit analysis processes in a series for continuous improvement, constantly optimize energy management processes and measures, and continuously improve energy efficiency.

Advantech effectively implemented the iEMS (Intelligent Energy Management System) intelligent energy management solution across its operating locations in the United States and Europe in 2023. Through digital professional integration technology, we provide energy consumption monitoring and management, HVAC energy efficiency management, air compressor energy efficiency management and other functional solutions. This solution featured energy efficiency management capabilities, which assisted organizations in optimizing energy consumption, enhancing energy efficiency, capitalizing on energy-saving opportunities, and facilitating carbon trading. The objective is to facilitate low-carbonization via digitalization, enable businesses to conserve energy and decrease emissions through the management of online data in order to drive offline improvement, and aid the Company in transitioning to environmentally sustainable operation.

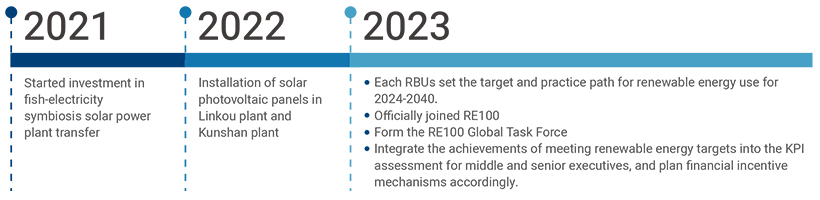

Since becoming an RE100 member in 2023, Advantech has actively promoted renewable energy development plans for its headquarters and overseas subsidiaries. The electricity consumption of Advantech's Taiwan headquarters and Kunshan, China, accounts for over 90% of Advantech's global electricity consumption. Consequently, Advantech's progress in implementing renewable energy will primarily focus on these two core manufacturing sites. For the disclosure of renewable energy-related data, please refer to the chapter on energy data management in the report. The implementation timeline and management model are as follows:

Management model

In the same year, Advantech officially established Advantech's global RE100 task force. The ESG Corporate Sustainability Development Office leads the coordination and progress review of renewable energy implementation, while the President of General Management conducts the review during the quarterly ESG regional meeting. The RBUs under this team span across Advantech headquarters and five countries/regions including China, the United States, Europe, Japan, and Korea. Each RBU has appointed renewable energy personnel to develop local plans that promote renewable energy compliance in line with local policies, regulations, and electricity price markets. The progress of achieving renewable energy targets in 2024 has been incorporated into the performance indicators of the Chairman and responsible management, and financial incentive mechanisms were also formulated and implemented.

Advantech prioritizes self-generation and self-consumption, and encourages local factories to install solar photovoltaic panels for self-generation and self-use. Examples include the installation of solar photovoltaic panels at the Linkou campus of the Headquarters, the Kunshan factory of China, and the New HQ phase-I facility (AASC-II) in the United States. The investment in the fish-electricity symbiosis solar power plant (located in Tainan, Taiwan), which started in 2021, is expected to open at the end of 2024. In the future, we hope to supply 5% of Taiwan's renewable energy in the first year. Secondly, purchase renewable energy directly from local areas. For example, Advantech's operating location in the Netherlands adopted direct purchase of local renewable energy generated from solar power and wind power. And, purchase renewable energy certificates based on local assessment needs. For example, Advantech Japan is actively negotiating matters such as the purchase of renewable energy certificates and renewable energy.