Goals and Strategies

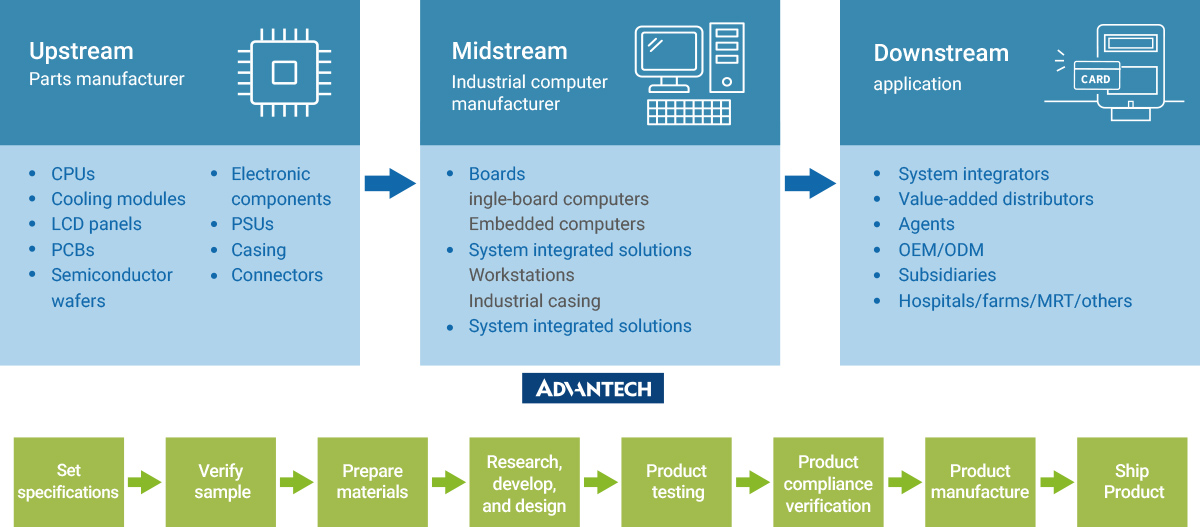

Advantech is committed to building a sustainable supply chain ecosystem for the IoT with the concept of creating a win-win situation as the core. The Company offers services to the IIoT industry, sourcing components from upstream manufacturers, conducting in-house assembly and production, and delivering the finished products to customers. Due to the characteristics of the industry, the purchased products are diverse and highly customized. Currently, the supplier database contains tens of thousands of supply items. To ensure supply chain stability and quality, and to understand its manufacturing process, Advantech regularly conducts supplier evaluations that cover quality performance and implementation, technical process capability, commercial cost management, local supply chain priority, and sustainability. We also maintain ongoing communication with suppliers to integrate corporate social responsibility and the concept of sustainable supply chain management into our evaluation criteria. It is hoped that through Advantech's sustainable supply chain management, suppliers can improve their sustainability capabilities and become our long-term partners. Furthermore, Advantech's Chief Operation Officer/COO regularly reviews supply chain procurement practices and management performance during the Meeting of Quality Management (MQM) to achieve supply chain sustainability management goals.

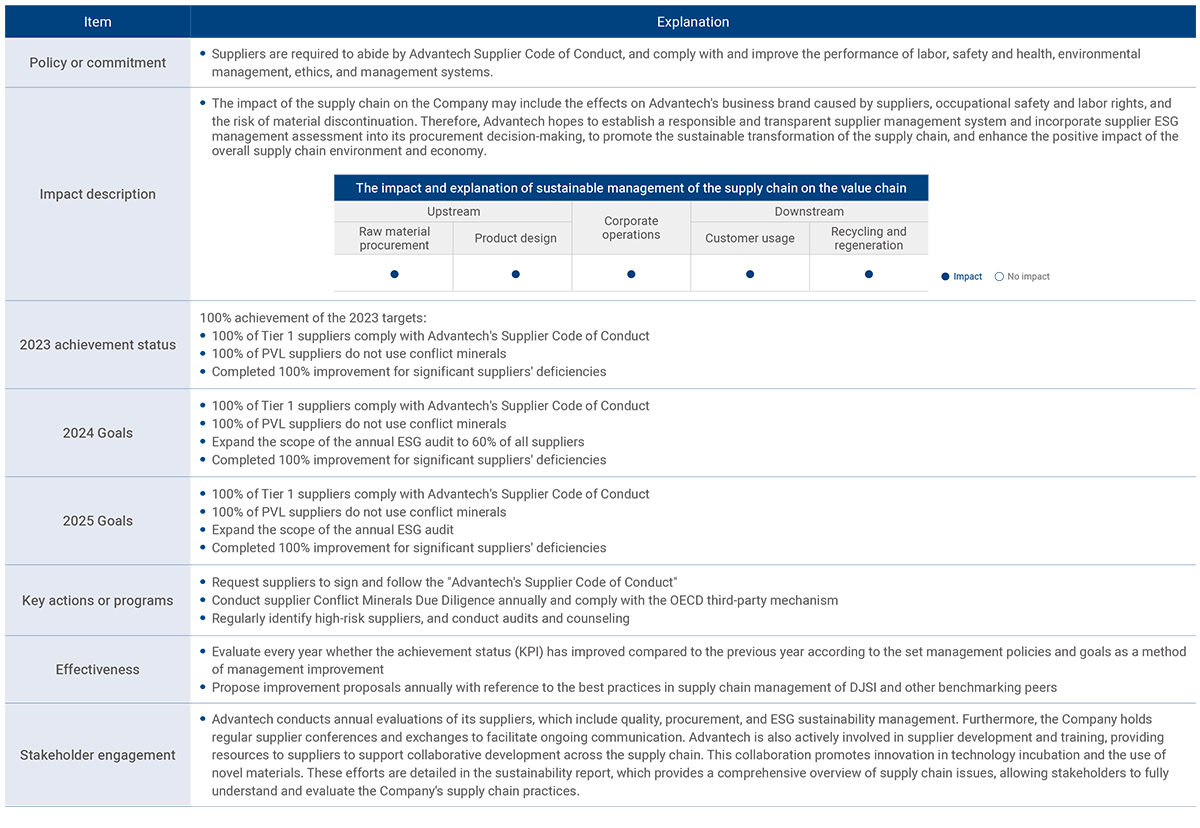

Management Guidelines for Major Topics

Goal of Sustainable Supplier Relationship Management

Project Highlights / Performance

Supplier Management

Supplier Composition

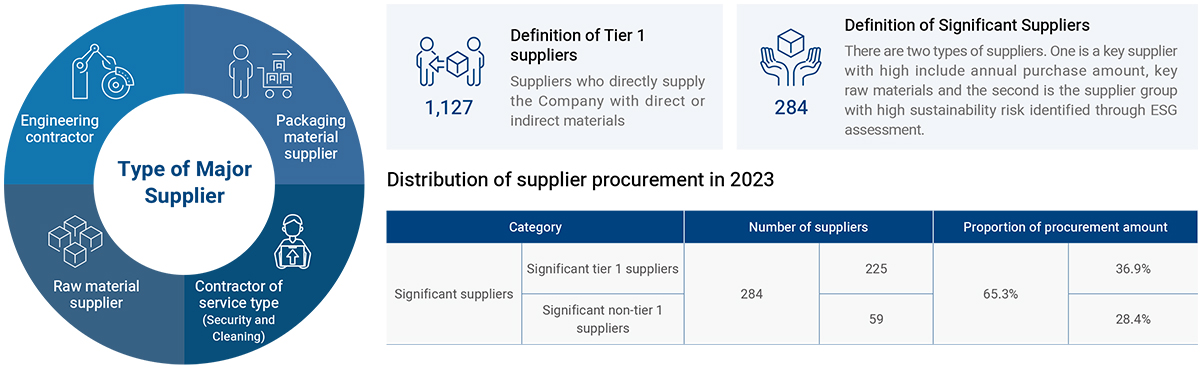

Advantech has a diverse and versatile product portfolio, with extensive product applications in fields such as IoT embedded computing, industrial computers and their peripherals, cloud computing, industrial automation, and communication systems. In response to the diverse product characteristics and applications, Advantech has developed a dynamic and highly interconnected supply chain system that encompasses a wide range of raw materials, including ICs, printed circuit boards (PCBs), electronic components, wires, plastic parts, metal parts, and packaging materials. Advantech's main supplier categories are divided into material suppliers and service-type contractors (such as security, cleaning, and engineering). In particular, material suppliers have a significant impact on operations and production. Consequently, Advantech defines material suppliers as tier 1 suppliers and categorizes them into two categories based on their attributes. These include direct material suppliers (materials directly related to production, such as main components and mechanical parts) and indirect material suppliers (materials not directly used for product production or auxiliary consumables, such as equipment, packaging materials, and alcohol).

To manage material suppliers and resource allocation effectively, Advantech subcategorizes suppliers to implement sustainability management. The supplier subcategories are: tier 1 suppliers and non-tier 1 suppliers, significant suppliers (including significant tier 1 and significant non-tier 1 suppliers), and high sustainability risk suppliers, as shown in the figure. In particular, suppliers with high annual procurement amounts, two types of suppliers, including those providing critical raw materials or irreplaceable items, and those identified as having high sustainability risks through ESG evaluations, are defined by Advantech as significant suppliers. To date, Advantech has identified 291 significant suppliers, which account for 82.5% of the total procurement amount.

Prioritize Locally procurement

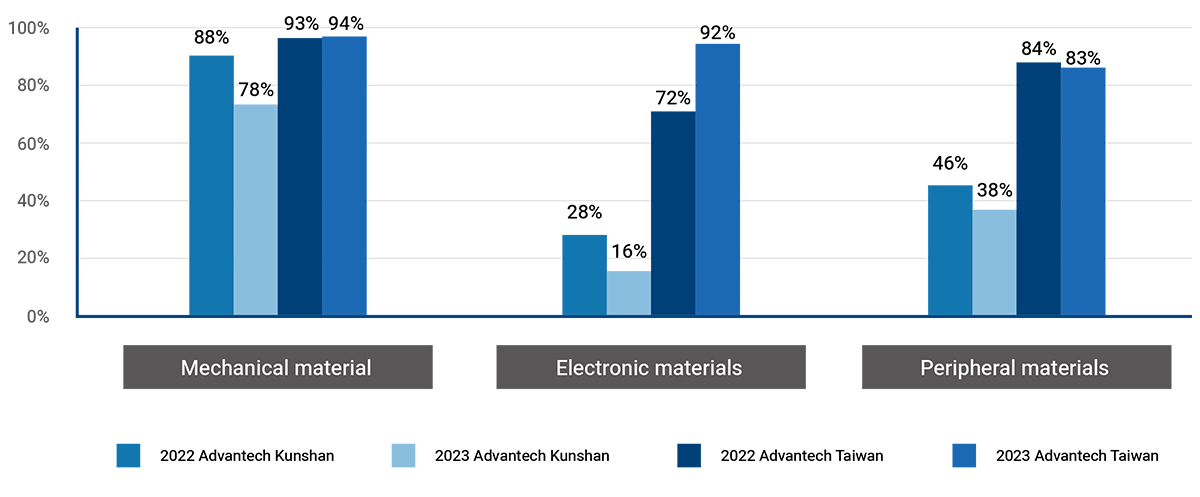

To bolster regional strategic cooperation and reduce CO2 emissions generated from manufacturing and transportation processes, Advantech continues to implement a localized procurement strategy, prioritizing local suppliers in its procurement activities over the years. Advantech's global operations span six Regional Business Units (RBUs). Given that the main manufacturing bases are currently located in Taiwan and Kunshan, the procurement strategies and performance disclosed in this report focus primarily on these two regions. Overall, Advantech Taiwan's local procurement amount in 2024 was NTD 10.9 billion, with a ratio of approximately 82%. Due to Advantech Taiwan's centralized procurement of some electronic components and peripheral raw materials, Advantech Kunshan's local procurement ratio accounted for about 43% of the total amount*, a slight increase compared to 2023. The overall local procurement ratio in 2024 was 68%. The summarized local procurement amounts and ratios of the Company in recent years are shown in Figure.

The proportion of the Company‘s local procurement amount in recent years is shown in figure.

Procurement locally ratio of Advantech Taiwan and Advantech China-Kunshan from 2023 to 2024

1 Definition of procurement locally: Advantech Taiwan – transaction counterparty is a manufacturer having a uniform invoice number for a for-profit enterprise in Taiwan; AKMC – transaction counterparty is a domestic manufacturer in mainland China.

2 Kunshan Electronics' decrease in the proportion of local procurement is mainly due to the switch to the self-purchasing strategy in 2020, but most of the self-purchasing suppliers are agents registered in Taiwan.

Supplier Management Strategy

Advantech believes that supply sustainability is a key commitment to corporate sustainable operation and recognizes the challenges to supply chain posed by factors such as geopolitics. Therefore, we aim to apply our consistent global brand strength to reinforce relationships with customers and partners worldwide, striving to create sustainable corporate value and build a mutually beneficial and thriving industry chain. Advantech has a global procurement unit and a quality management unit to implement supplier management. Based on the principle of cooperation and symbiosis, Advantech manages supplier selection criteria and processes, conducts risk assessments, performance evaluations, audit counseling, education and training, and hosts supplier conferences to incorporate sustainability requirements into day-to-day supply chain management. Advantech’s procurement strategy focuses on diversifying procurement risks and reducing costs. To ensure substitutability and maintain competitiveness, at least two suppliers are selected for materials. For electronic components with high commonality, a second source management mechanism has been established. Moreover, safety stocks of key materials are maintained to mitigate risks arising from supply shortages or quality issues. Advantech categorizes materials by tier and assigns dedicated procurement personnel to analyze market information. By regularly reviewing market trends and adopting a centralized procurement strategy, Advantech establishes a list of PVL suppliers and monitors their capabilities in cost, quality, delivery date, and supply continuity to enhance collaboration efficiency and obtain high-quality materials with stable delivery times.

In addition to evaluating the labor, environment, and business ethical management of Advantech‘s operations in accordance with the RBA Code of Conduct, Advantech also actively requests the sustainable management of the supply chain by requiring suppliers to sign the “Supplier Code of Conduct Consent.” In addition to local laws and regulations, we also regulate business behavior in various aspects such as labor rights and interests, health and safety, environment, business ethics, and management systems. At the same time, Advantech requires suppliers to communicate sustainability requirements to their next-tier suppliers by signing the “Supplier Code of Conduct,“ so as to promote the implementation of sustainable practices throughout the supply chain and forge a more resilient and impactful supply chain by taking action.

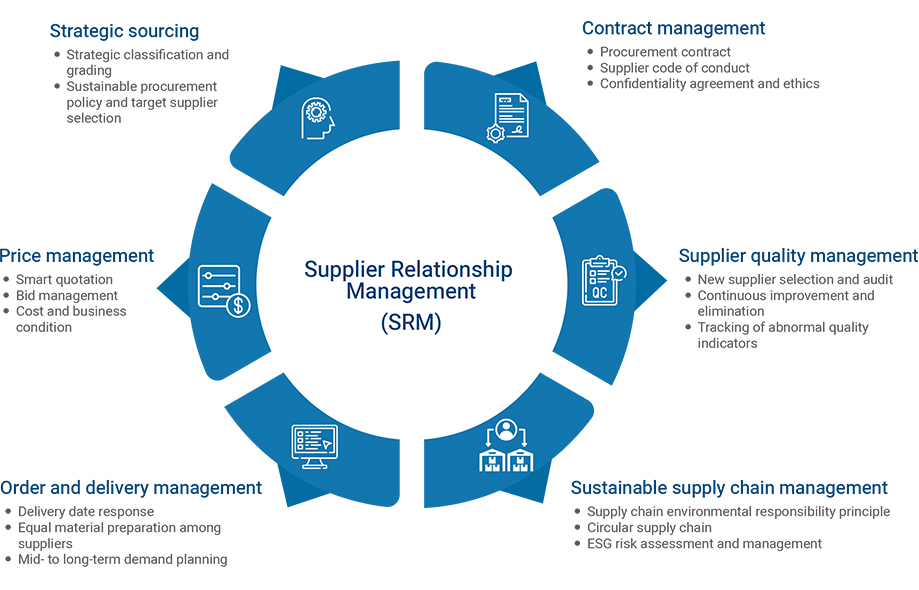

Supplier Relationship Management

Supplier Management

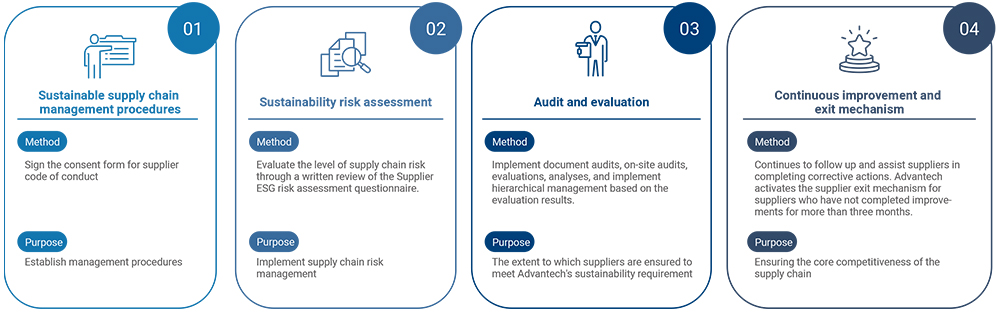

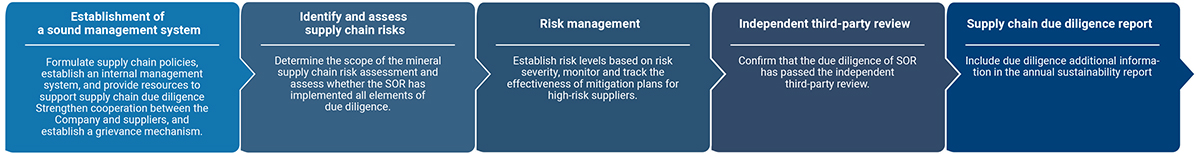

To implement Advantech's procurement and supply chain policy, Advantech has established a four-stage supply chain sustainability management process. Through the annual rolling improvement, circular, and exit mechanism, we ensure that suppliers meet Advantech’s standards and improve their sustainability performance.

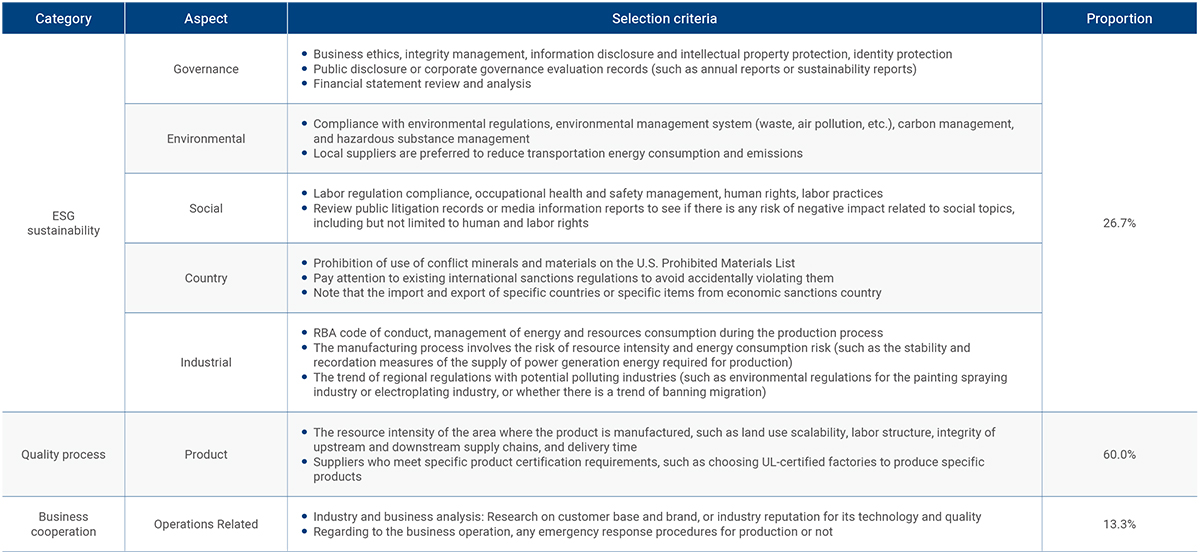

Supplier Sustainability Evaluation

Advantech has established ESG thresholds for its suppliers (including new suppliers and existing suppliers). To become an Advantech supplier, in addition to signing the supplier code of conduct, PCB suppliers are also required to pass ISO 9001 and ISO 14001 certifications. In addition, in order to understand and identify potential risks in the supply chain, Advantech refers to the Supplier Selection Criteria when conducting supplier screening. During the screening process, factors such as sustainability or business operations are also considered to conduct a supplier survey and evaluation. The ESG screening for but not limited to governance, environmental, social, country, industry, and product collaboration, product and business operation relevancy accounted for 26.7% of the overall procurement evaluation, and was listed as priority conditions of Advantech suppliers. The overall supplier screening items include the following:

Supplier Risk Identification and Audit Counseling

Significant suppliers ESG audit deficiencies and improvement actions in 2024

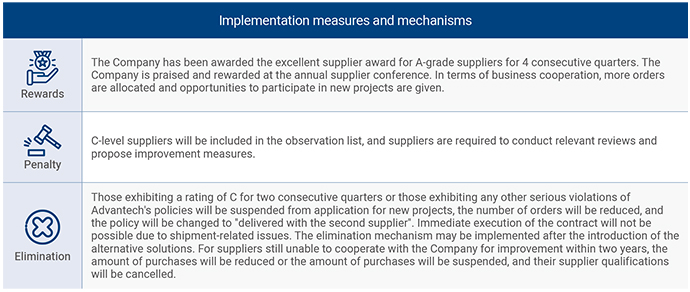

Supplier Evaluation and Elimination Mechanism

Supply Chain Sustainability Improvement Plan

In 2024, Advantech continued to advance its supplier improvement program by empowering and training its partners to enhance their sustainability capabilities, ensuring alignment with ESG requirements and strengthening sustainable supply chain management. Advantech plans multi-level training activities for different supplier categories and needs, including supplier code of conduct courses, supplier conferences, carbon management courses, and theme workshops, comprehensively covering environmental, social, and governance topics while emphasizing practical application and capacity building. In 2024, three themed workshops were held for 122 representatives from 64 significant suppliers (accounting for 22% of all significant suppliers). Counseling resources were planned based on supplier types, providing empowerment courses on intelligent energy solutions, SDG topics, as well as environmental, health, and safety (EHS) practices, laying a robust foundation for the sustainable development of the supply chain.

In 2025, Advantech will continue to strengthen the suppliers' sustainable development capabilities. To ensure precise allocation of counseling resources and continuously enhance fundamental sustainability literacy, Advantech will adopt a categorized management approach based on suppliers’ characteristics and needs. Multi-level, theme-based learning and exchange mechanisms will be designed accordingly to different suppliers with adequate support. The new year plan encompasses core topics like renewable energy, carbon management, biodiversity, and sustainable information disclosure. It will provide more in-depth and targeted learning opportunities through medium and large-scale forums, small workshops, and project-based counseling for high-carbon emission suppliers. Furthermore, Advantech will join forces with industry benchmarks, government agencies, academic institutions, and research institutions to integrate diverse professional resources, share the latest industry trends and practical experiences, assist suppliers in understanding important development trends and sustainable implementation strategies, and ensure that both suppliers and Advantech achieve their long-term sustainable development goals (SDGs). Advantech's ESG Training Program for Procurement Personnel and Internal Stakeholders (including Operations, ESG Office, R&D, Finance, Investor Relations, Senior Management, etc.) for 2024 The training courses covered the following areas:

1. Carbon Management: Accelerating Net Zero!Internal Carbon Pricing Governance Rules: Understanding governance practices for internal carbon pricing.Sustainability Initiatives: Defining sustainability goals and setting a scientific approach to carbon reduction.Corporate Sustainability Benchmarks: Advancing towards a net-zero emission, low-carbon transformation.

2. ESG General Awareness:Global Sustainability Commitments Review: A comprehensive overview of global progress on sustainability and net-zero targets.ESG Essentials From Concepts to Actions – A mandatory introduction to ESG principles and how to implement them in business operations.

3. Biodiversity: The Next Step in Corporate Sustainability!Trends and Frameworks in Biodiversity: Exploring the latest trends and frameworks in corporate biodiversity management. Carbon Credits and Forest Carbon Sequestration: Examining the real and illusory aspects of forest carbon credits, and whether tree planting alone can offset carbon emissions.

4. ESG Executive Courses:ESG Corporate Case Studies: Practical, real-world examples of ESG implementation in companies.New Business Opportunities in Sustainability: Understanding new business opportunities arising from the global shift toward sustainability.

2023~2024 annual improvement and empowerment results

Conflict Mineral Procurement Management

Tantalum, tin, tungsten, and gold (collectively known as 3TG minerals) are key materials for the operation of electronic products. Our global product portfolio, including industrial computers and peripherals, cloud computing and industrial automation, communication systems, IoT intelligent systems, and embedded platforms, relies heavily on these materials, especially electronic components. For example, tin is used in solder, tantalum in capacitors, tungsten in electrical contacts, and gold in electrical connection coatings. These components are crucial to our products.

To ensure the avoidance of minerals from Conflict-Affected and High-Risk Areas (CAHRAs), Advantech rigorously complies with the Responsible Business Alliance (RBA) Code of Conduct and implements a conflict-free minerals policy. Advantech not only refrains from procuring metals from CAHRAs but also requires its suppliers to comply with this policy, ensuring that the supply chain respects human rights and is not involved in conflict activities. As of 2024, 100% of Advantech's PVL suppliers have signed the "Declaration of Non-Use of Conflict Minerals," and all of Advantech's products are guaranteed to be conflict-free.

As a brand company, Advantech does not directly purchase raw ore or unrefined 3TG minerals. Due to the multiple tiers involved in the supply chain, once the raw ore is smelted, refined, and transformed into ingots, gold bars, or other mineral derivatives, its origin becomes difficult to trace. Smelters and Refiners (SORs) serve as key control points for raw ores and are best positioned within the supply chain to verify the origin of minerals. Suppliers who engage in direct collaboration with Advantech and influence procurement decisions are considered PVL suppliers. Advantech relies on them to identify and assess supply chain risks and provide relevant information on 3TG mineral SORs.

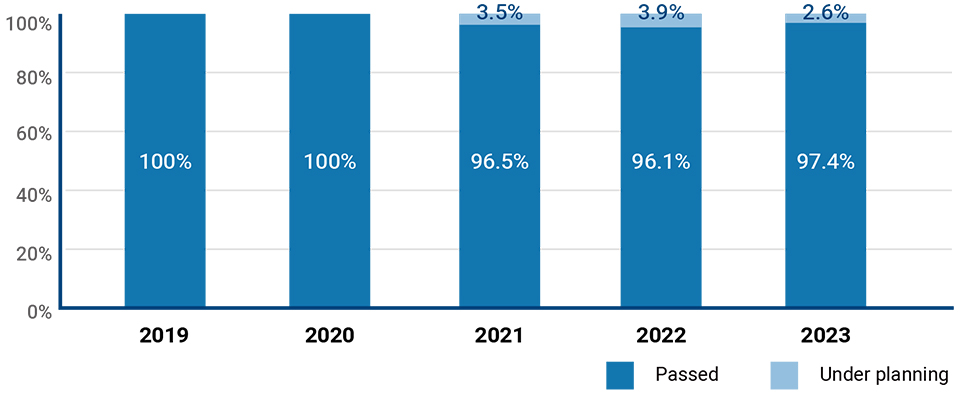

Advantech continues to comply with the "Due Diligence Guidance" of the Organisation for Economic Co-operation and Development (OECD) as the basis for its "Conflict Minerals Management Plan". The Company investigates the mineral sources of its suppliers through the Conflict Minerals Reporting Template (CMRT) to confirm whether the 3TG smelters have passed audits by independent third-party organizations such as RMI, LBMA, or RCJ. Moreover, Advantech has expanded its sources of component suppliers to minimize risk, avoid reliance on single suppliers, and demand the supply chain to establish diverse procurement channels. If a non-compliant smelter is identified in the supply chain, Advantech will require the supply chain to either switch to a compliant alternative smelter certified by the aforementioned audit organizations and submit a removal plan for the non-compliant smelter, or assist the relevant smelter in passing an independent third-party audit to ensure the compliance and sustainability of the entire supply chain.

According to the conflict minerals due diligence results for 2024, we identified 222 smelters in our supply chain. Among these, 215 smelters have been certified as meeting the "Responsible Minerals Assurance Process (RMAP)" standards (or equivalent cross-recognition assessments). There are currently seven smelters in the certification process, with qualified smelters achieving a compliance rate of 96.8%.

2024 conflict minerals survey smelter distribution

In addition to 3TG, we have expanded the scope of our survey to include cobalt and mica in 2024. Cobalt is a key material for manufacturing batteries and magnetic alloys, while mica can be used in the exterior coatings of electronic products. This year's due diligence identified 83 cobalt smelters and seven mica smelters.