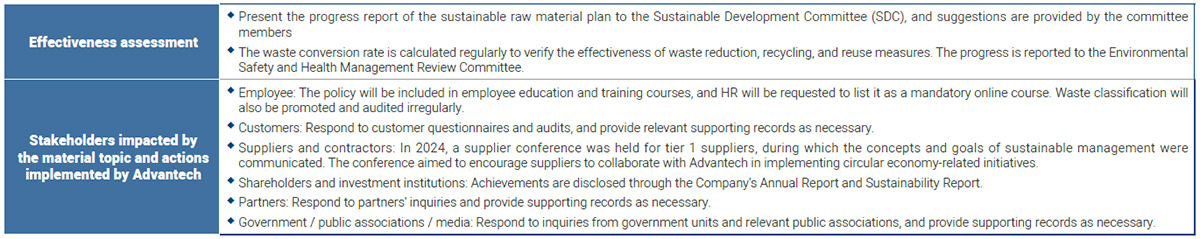

Policy and Actions

Environmental Responsibility

Advantech is well aware of the environmental impact of its product manufacturing processes. Consequently, in fulfilling our environmental responsibilities, we have adopted the ISO 14001 environmental management system to identify environmental risks and opportunities, and ensure that all our plants comply with local regulations and stakeholder expectations. To this end, we conduct internal audits annually and obtain third-party certification to implement the requirements of the ISO 14001 environmental management system. At the same time, to foster environmental awareness among our colleagues, we have developed training courses on the Company's policies and management measures for water conservation, waste reduction, and resource recycling, providing Advantech employees with environmental responsibility education. This requirement extends beyond new colleagues, as all our current colleagues are required to complete annual on-the-job training to make sure that all employees understand our latest environmental policies. The Company's environmental policy is confirmed and committed to by the Board of Directors before it is announced on the official website.

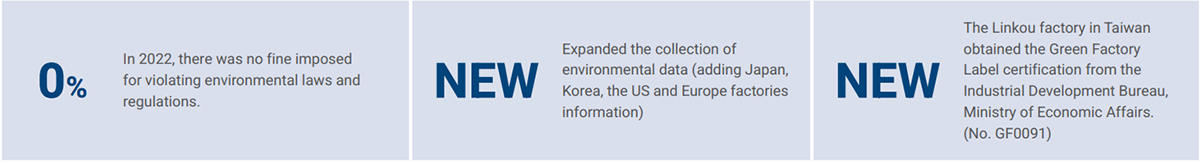

Highlighted Performance

Environmental Promotion Procedures and Actions

Environment-related certification of Advantech’s main global operations and production factories

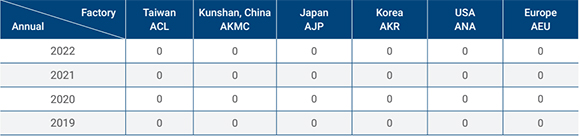

Statistics on Environmental Violations at Advantech’s main global operations and production factories

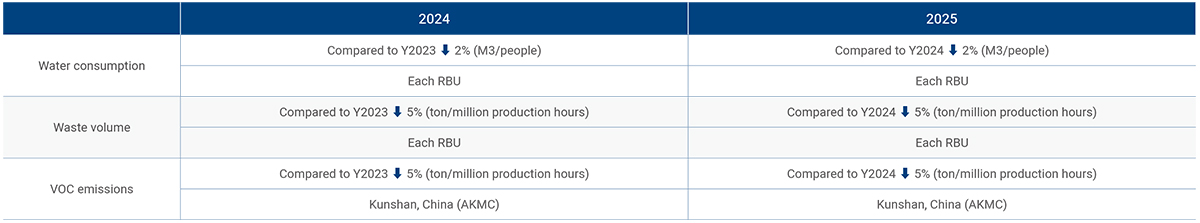

Since 2022, aside from its Taiwan headquarters and Kunshan plant in China, Advantech has expanded the collection of environmental data to include facilities in AJP, AKR, ANA, and AEU. In 2023, the Company set environmental management targets for each RBU or production plant. Their achievement status in 2024 and targets for 2025 are outlined in the following table.

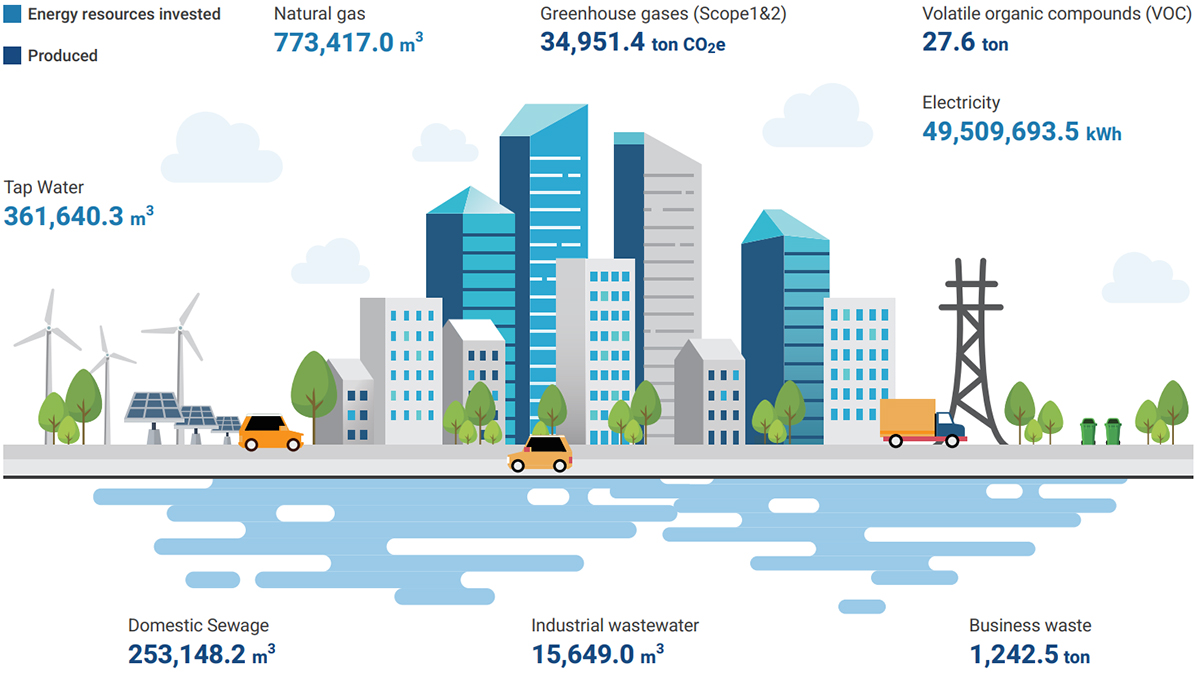

Energy and Resource Use and Waste Management

Water resource risk management and water consumption/sewage management

Advantech utilizes the World Resources Institute (WRI) Water Risk Atlas analysis tool to confirm the water resource risks at its significant locations of operation and production plants (as shown in Figure), and disclose the sources of water withdrawal and the receiving water bodies for discharge in each region, as detailed in Table 4.4.3. According to the analysis results, Advantech's significant locations of operation and production plants generally face low to medium water resource risks, except for the Kunshan plant in China, which faces a high water resource risk. Using the results of the water resource risk analysis, Advantech plans and manages its water resources according to the risk level at its significant locations of operation and production plants, ensuring effective and sustainable water use.

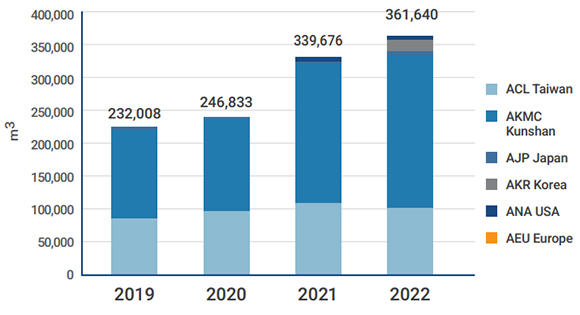

All of Advantech's offices and plants are situated in developed industrial zones or parks within metropolitan areas, utilizing tap water as their primary water source, without relying on groundwater or well water. Their production processes are primarily assembly-based rather than water-intensive, and water consumption is mainly for domestic purposes. As such, overall consumption is low and does not pose a significant environmental impact on water resources. Even so, Advantech still follows the ISO 14001 environmental management system to identify water consumption and sewage treatment processes, explore water conservation opportunities, actively promote water-saving management programs, and strive to reduce water consumption and sewage discharge to ensure the proper management of water resources. The total water consumption of Advantech's significant locations of operation and production plants worldwide for the last four years is shown in Figure .

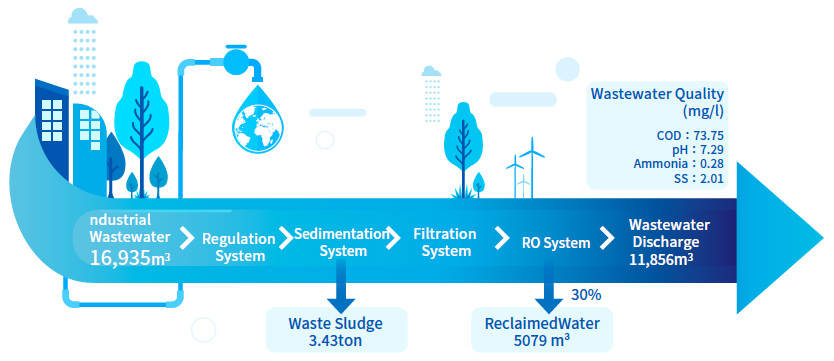

Advantech's plants continue to explore water conservation possibilities. In employee activity areas, rainwater harvesting systems are installed for toilet flushing and park irrigation, and intelligent irrigation systems are also implemented to save water. In addition to using water-saving faucets and toilets, employees are required to participate annually in environmental responsibility education and awareness training on water efficiency management programs, which are embedded in Advantech’s corporate culture. Regarding chiller systems used by ACL, intelligent temperature control is implemented to accurately regulate the temperature and humidity of the work areas, avoiding unnecessary water waste. ACL's total water consumption in 2024 decreased by approximately 4,666 m³ compared to 2023. As for the Kunshan plant in China, due to the higher water resource risk it faces compared to other plants, the plant has continued to implement projects such as reclaimed water reuse and overflow water reuse since 2022. The aim is to recycle sewage from the production process back to the plants for reuse as much as possible, thereby reducing the plant's reliance on tap water. In 2024, the Kunshan plant's total water consumption decreased by 14% compared to 2023, amounting to roughly 24,862 m³, while the sewage recycling rate was 30%. The United States AASC plant implemented a water-saving optimization plan for its irrigation system in 2023. To protect plant health, the system was continuously optimized and adjusted, resulting in an additional 15% water savings in 2024, amounting to about 632m³ of water. This goes to demonstrate the United States AASC plant's emphasis on water resource conservation. Water consumption of Advantech's significant locations of operation and production plants worldwide in recent years is summarized in Table .

-

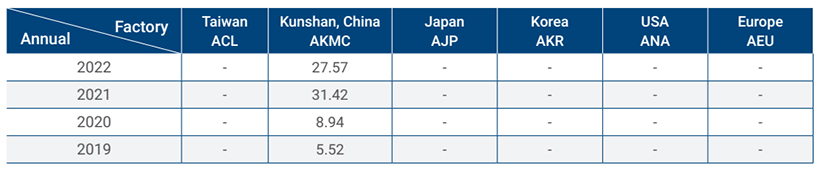

Advantech factory water consumption in recent years

*Note: No water consumption statistics was recorded for Korea in 2021

*Note: No water consumption statistics was recorded for Korea in 2021 -

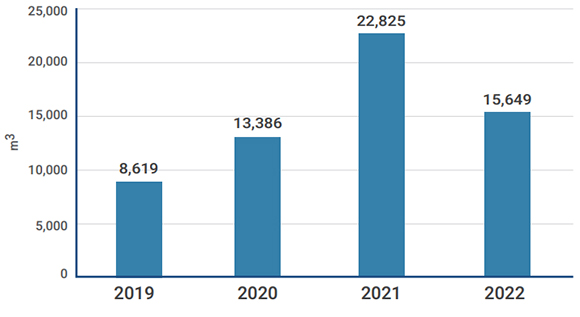

Discharge of industrial wastewater by Advantech’s main operating locations and production factories in recent years

*Note: Only AKMC discharges industrial wastewater among Advantech’s main operating locations and production factories.

*Note: Only AKMC discharges industrial wastewater among Advantech’s main operating locations and production factories.

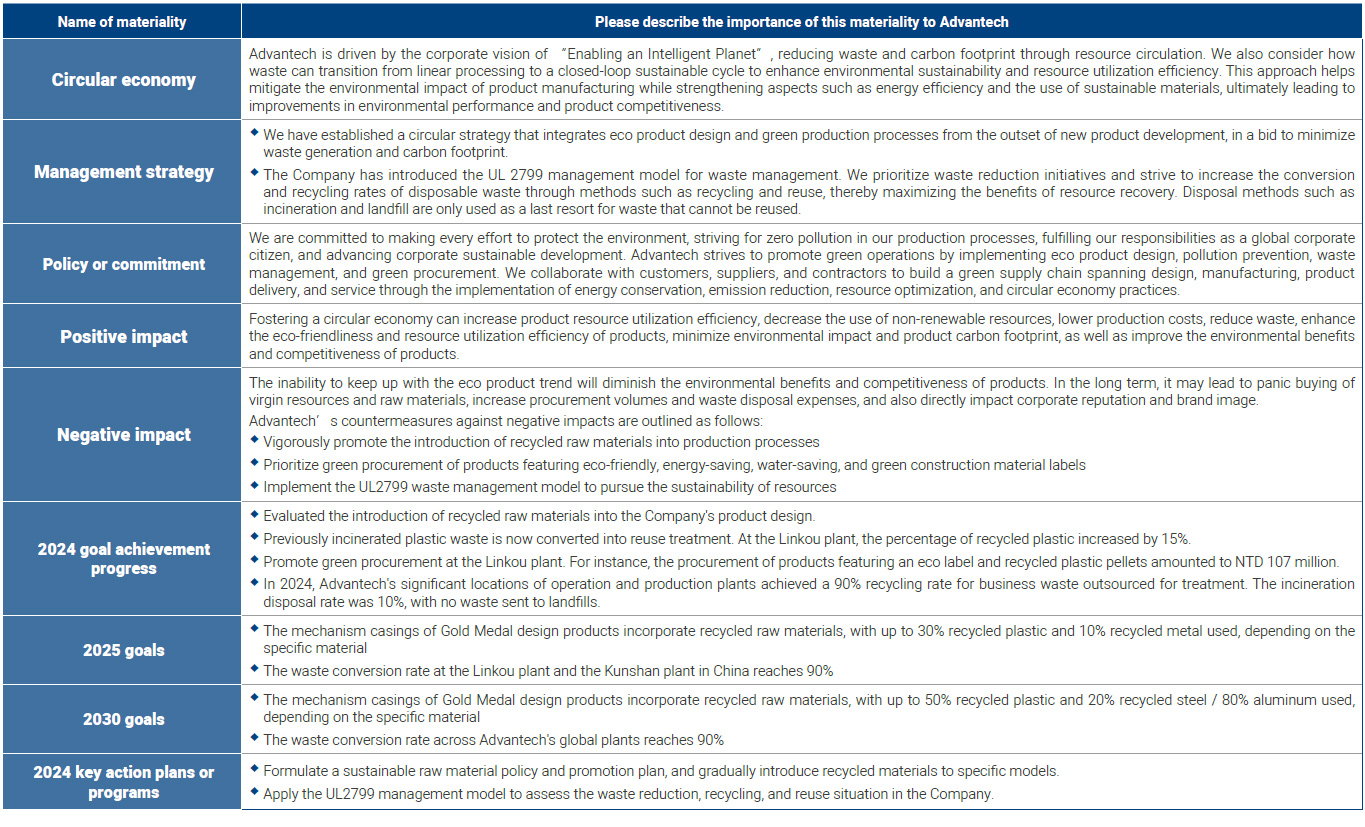

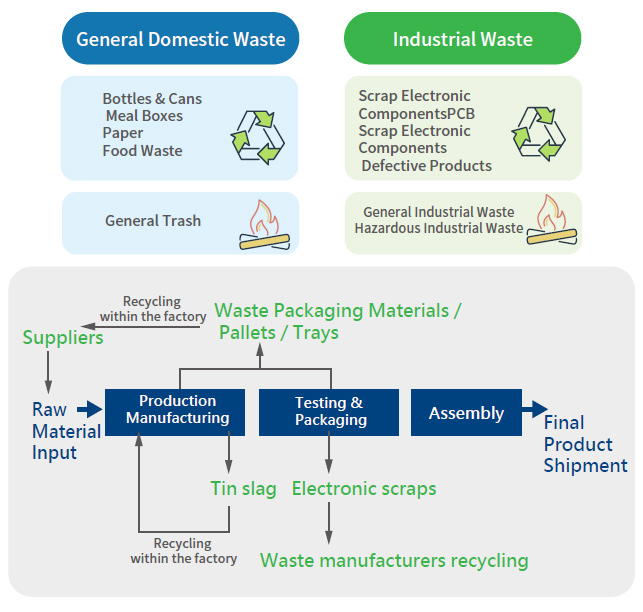

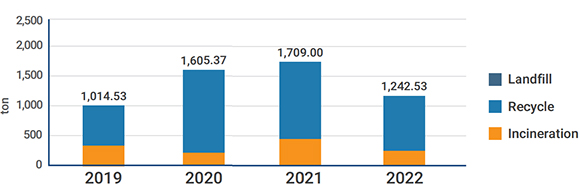

Waste management and circular economy

Advantech is dedicated to implementing the zero waste to landfill policy and the plant business waste reduction, recycling, and reuse program. As of 2024, Advantech has implemented the UL2799 zero waste to landfill standard management, beginning with our ACL facility. Currently, Advantech no longer uses landfills to dispose of the waste. Furthermore, we are optimizing our waste management, re-evaluating waste categories and flows, and exploring more opportunities for waste recycling to reduce the possibility of waste going directly to incineration plants, in turn improving the waste conversion rate. In 2024, the self-assessed waste conversion rate for Advantech's significant locations of operation and production plants worldwide was 74% (the calculations for ANA, AEU, AJP, and AKR only included the amount of business waste, and certain internally recycled resources were not included). Meanwhile, Advantech also adheres to the ISO 14001 management system standards to ensure that waste disposal contractors and their disposal methods comply with local regulations. To accurately understand the waste disposal situation, Advantech regularly conducts audits of waste disposal contractors according to the law to ensure that all outgoing waste is disposed of legally. During the waste disposal contractor selection process, factors such as whether they have obtained/passed relevant qualifications are included in the evaluation. After waste is transported off-site, the Company verifies its legal disposal through government reporting platforms or by reviewing disposal certificates provided by contractors. If necessary, Advantech also conducts on-site inspections of waste treatment facilities to ensure that waste handling processes and contractor service quality comply with Advantech’s standards and regulatory requirements. In 2024, there were no major breaches of contract or legal violations by any of Advantech’s waste contractors.

In terms of waste recycling and reduction, Advantech not only works with end-of-life recyclers to convert waste into recycled raw materials but also collaborates with upstream suppliers. This includes initiatives such as recycling and reusing packaging materials, reusing wooden pallets, and modifying PCB designs to reduce edge scraps. Waste generation is minimized in the plants by reusing solder dross. Through collaboration among the plant, suppliers, and waste disposal contractors, Advantech aims to minimize waste incineration, reduce environmental impact, and achieve sustainable resource circulation. In addition, Advantech's Kunshan plant in China launched a research project in 2023 to transition from liquid painting to powder coating. The project was fully implemented in 2024, resulting in a reduction of approximately 30 tons of lacquer residue waste. The Company's waste management model is shown in Figure.

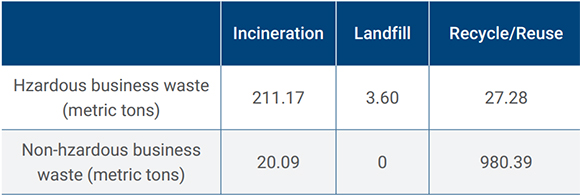

Statistics indicate that the total business waste disposal outsourced by Advantech's significant locations of operation and production plants in 2024 was about 1,074.92 metric tons, of which non-hazardous waste amounted to 919.61 metric tons (85.55%), and hazardous waste was 155.31 metric tons (14.45%). For hazardous business waste, the recycling rate was 41% (63.28 metric tons), while 59% (92.03 metric tons) was incinerated. As the weight of domestic waste is estimated based on the cleaning contract and lacks detailed classification of disposal methods, only the disposal information for business waste is disclosed. For waste disposal method, please refer to Table and Figure.

-

Waste disposal methods of Advantech's main operating locations and production factories in 2024

*Note:

*Note:

1. Waste weight statistics for ACL and AKMC are based on data reported by each plant to the competent authority, while statistics for AJP, ANA, and AEU are based on outsourced disposal data. -

Business Waste Disposal Status among Advantech's Main Global Operations and Production Factories in Recent Years

*Note:

*Note:

1. Waste weight statistics for ACL and AKMC are based on data reported by each plant to the competent authority, while statistics for AJP, ANA, AEU, and AKR are based on outsourced disposal data.

2. No waste generation statistics were recorded for Korea between 2021 and 2023.

Air Pollutant Management

Advantech compiled air pollution data and information disclosure into three key points:

Advantech's production process does not produce ozone depleting substances (ODS), and therefore there are no ODS emissions.

The primary source of VOCs at the Kunshan plant in China is process emissions. The VOC emissions are uploaded to the government environmental reporting website according to local regulations. The annual VOC emissions comply with local regulatory requirements.

Advantech's other production plants primarily focus on assembly processes, which generate minimal air pollution. As a result, these facilities do not emit significant levels of nitrogen oxides (NOx), sulfur oxides (SOx), or volatile organic compounds (VOCs).

Volatile Organic Compounds (VOCs) Emitted by Advantech’s Main Global Operations and Production Factories in Recent Years (Unit: mt)

To implement environmental reduction targets, Advantech’s Kunshan plant in China has adopted effective VOCs control measures. These include real-time continuous online monitoring, outsourced testing for emission management, and improvements in equipment processing efficiency to lower overall emissions. In recent years, improvement projects have been implemented in succession, including the transformation of process technology, the switch from liquid painting to powder coating to address waste gas, and the enhancement of equipment processing efficiency on production lines, effectively minimizing the generation of energy, waste gas, and VOCs. In 2024, VOC emissions decreased by approximately 50% compared to 2023. The use of organic solvents in the relevant painting production lines was reduced by 81.3 tons, and as can be seen from Figure 4.4.6, VOC emissions from Advantech’s Kunshan plant in China exhibit a year-over year downward trend.

Biodiversity and Conservation of Forests

Advantech started to focus on the topics of biodiversity and conservation of forests in 2022. Moreover, we joined the Taiwan Nature Positive Initiative (TNPI) initiated by the Taiwan Business Council for Sustainable Development (BCSD-Taiwan). We take more active actions on this issue to increase Advantech's corporate resilience. Moreover, Advantech's IoT expertise is being applied to empower nature conservation.

Sustainable Forests and Green Office

Advantech headquarters and major overseas business units have implemented the green office plan. We promote a paperless office environment by encouraging doublesided printing, implementing paper recycling practices, and prioritizing the use of FSC (Forest Stewardship Council)-certified sustainable paper or other recycled paper materials for office and household use. In terms of eco packaging material planning, Advantech utilizes recycled paper for all its shipping cardboard boxes and also provides FSC-certified sustainable forest cardboard boxes as a customer option to meet market requirements.

As part of its forest conservation efforts, Advantech sponsors the “Taichung Dadu Plateau Ecological Afforestation Project” led by the Taiwan Forestry Restoration Association. The project aims to cultivate 6,000 seedlings across 75 species, with over 70% consisting of native tree species from the Taichung coastal and shallow mountain regions. These seedlings will be provided to the Taichung City Government for forest restoration and tree planting purposes. In addition, with public welfare in mind, they will be made available to public agencies for ecological afforestation initiatives. The funding will be used for seed collection for seedlings, growing local native species seedlings, mountain forest ecological education, and seedling growth monitoring. The support project is expected to plant 0.8 hectares of trees and sequester 1.76 metric tons of carbon. The Company has also disclosed no-deforestation commitment on our ESG official website to implement our corporate commitment.

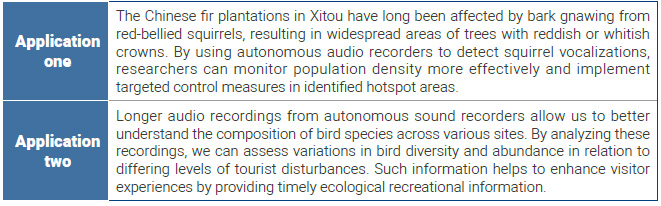

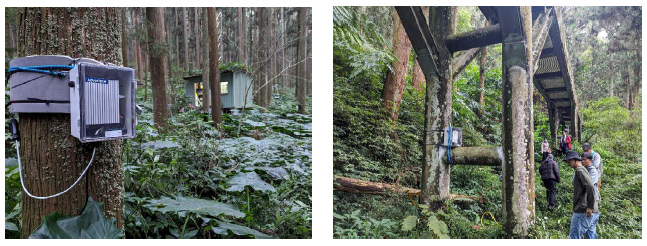

AIoT for Biodiversity: Bird Sound Monitoring and AI Automatic Identification Solution

Building on the achievements of the previous project, this project combines Passive Acoustic Monitoring (PAM) and AI-powered SILIC (Sound Identification and Labeling Intelligence for Creatures) to enhance the efficiency of wildlife monitoring, reduce labor costs, improve spatiotemporal resolution, and improve the effectiveness of forestry in both monitoring and decision-making. Based on the validation conducted at the NTU Experimental Farm in 2023, the project was extended to the NTU Experimental Forest in 2024. Equipment was deployed in selected locations, including newly afforested areas, flux towers, aerial corridors, and the Guanshan parking lot, to further verify and expand the application of AIoT technologies in environmental monitoring.

In 2025, Advantech will continue addressing challenges in wildlife monitoring, including equipment power supply, data upload, and real-time transmission. Also, we will explore a wider range of smart forestry applications, such as wildfire prevention, soil carbon sequestration, and river hydrology management. Through large-scale deployment and implementation, Advantech aims to establish a comprehensive environmental monitoring framework. Based on this infrastructure, we can enhance predictive and preventive capabilities to minimize the occurrence of natural disasters and mitigate their potential impacts on biodiversity and society.

Besides soundscape ecology research, this project also offers practical application value for forestry:

Biodiversity initiatives of Advantech’s overseas subsidiaries

Advantech China Biodiversity and Plastic Reduction Family Day: Advantech China (ACN & AKMC) incorporated the theme of biodiversity into its Family Day activities across six locations: Shanghai, Beijing, Shenzhen, Guangzhou, Xian, and Kunshan. The activities featured nature education and family interactions, including popular science education on animals and plants, a “Plastic-free Commitment” environmental creativity challenge, leaf recycling DIY projects, water resource experiments, and bird nest building. These engaging and educational activities helped Advantech employees and their families better appreciate the beauty of nature and the importance of ecology

Advantech Europe created bee hotels for 20,000 bees: Advantech's the Netherlands subsidiary used its office space to form a micro-ecosystem and installed Advantech monitoring equipment in the beehives to monitor honey production, bee sounds, and bee activities effortlessly. During the honey harvest season, Advantech Europe collaborates with local small farmers to harvest and package honey. The Company also invites employees and their families to design 137 illustrations for the honey jars, fully showcasing local biodiversity engagement.

Advantech Europe's involvement in local environmental education: Advantech's the Netherlands subsidiary is situated adjacent to a public park. The local municipality plans to invite nearby businesses in the science park to collaborate on planning a biodiversity park project, focusing on the construction of insect hotels, to benefit local primary school science education.

Advantech Korea Advantech Korea (AKR) held an “Advantech Volunteer Day” that combined biodiversity education and litter cleanup through the “City and Ecological Park Plogging” initiative, where participants jogged while picking up litter to protect the environment. Additionally, the “Advantech Creators Club (ACC)” led 25 employees in creating “Net-Zero Pop-Up Books” and “Environmental Jigsaw Puzzles,” which were donated to local children's centers to embed carbon reduction and ecological awareness in the next generation's growth and development.